Table of Contents

There are different types of devices for detecting gas leaks. We distinguish here between pump and diffusion devices. For everyday work, it is important to know the difference, as the gas indications of the respective device type must be evaluated differently. In which cases does it make sense to use a pump device? When is a diffusion device advantageous? What are the differences in working methods and procedures?

Gas meters with diffusion system

When assessing a gas indication, the technician must know what type of measuring device he is using and how to assess the indication. A diffusion measuring device with a gooseneck collects escaping gas in the sensor head, such as the VibraGas Ex or the LeckOmio Ex. The display therefore depends very much on the position of the sensor head and the length of the measurement.

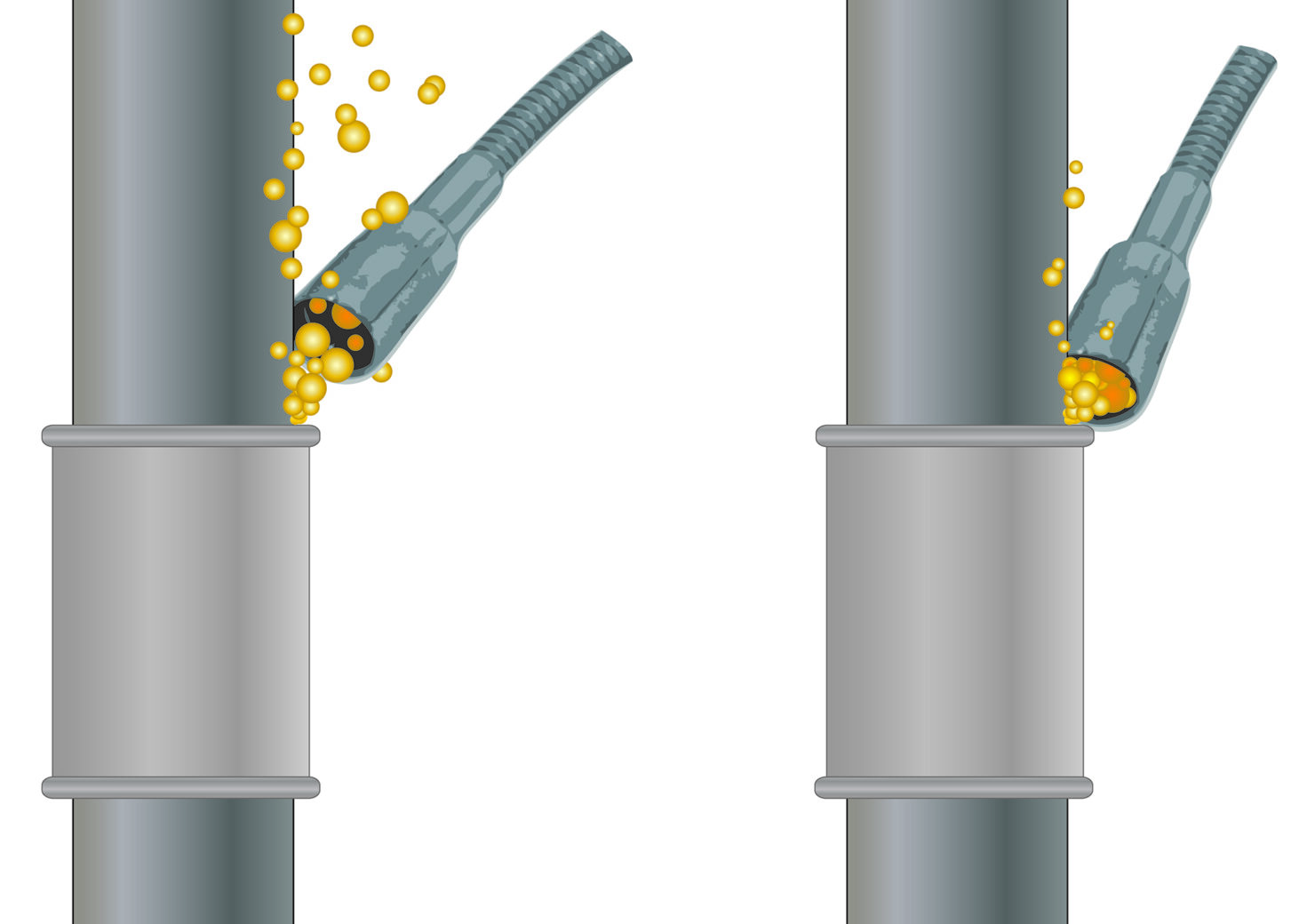

The importance of the probe in diffusion gas meters

When using diffusion devices, the positioning of the probe head at the gas outlet point is very important. Even at a small distance from the outlet point, only a small proportion of the gas will diffuse into the sensor head and therefore only a relatively low concentration will be indicated. If, on the other hand, the sensor head is positioned directly above the outlet point, the gas will catch in the sensor head and the highest concentration readings will be obtained.

In the case of diffusion devices, the measurement is carried out with the sensor head directly at the pipe or the connection point until the maximum display is reached. If the maximum reading is less than 1,000 ppm, no measures are necessary. If the maximum reading is more than 10,000 ppm (1 vol.%), sealing must be arranged.

Pump measuring device

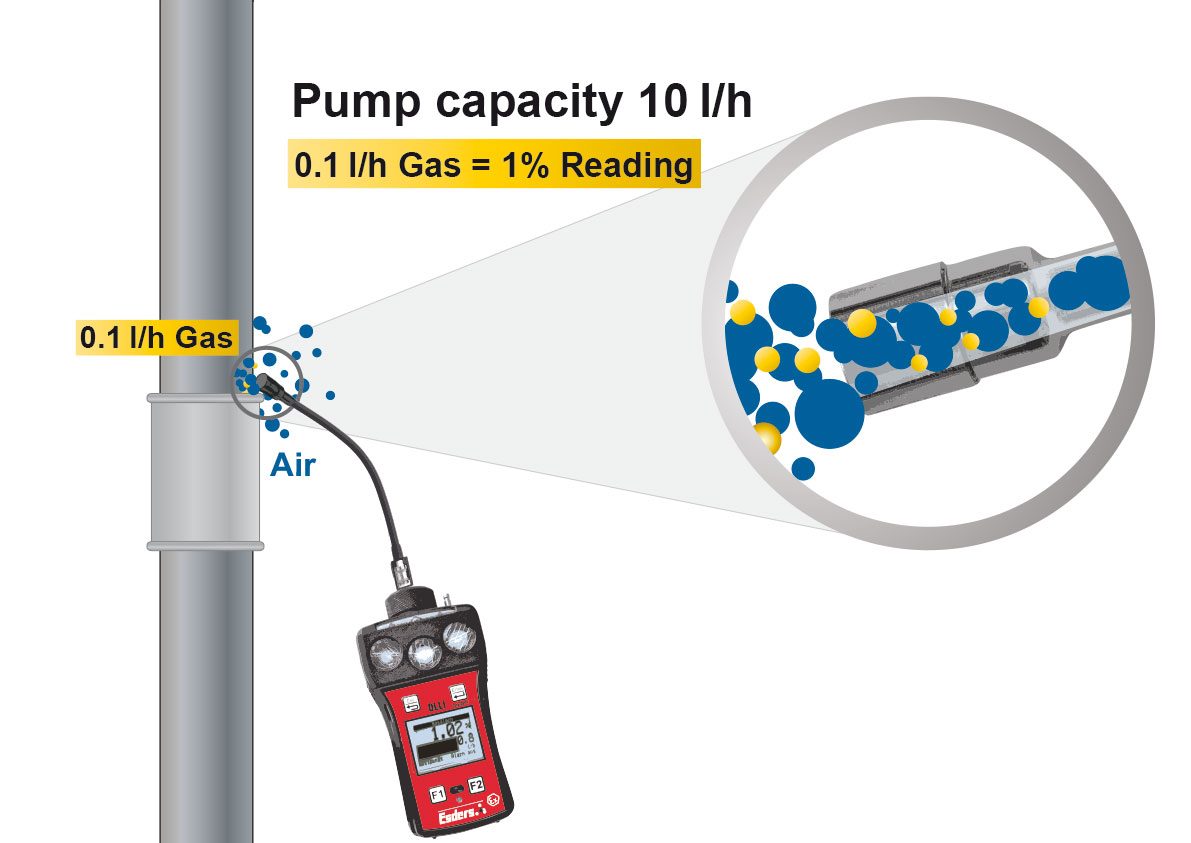

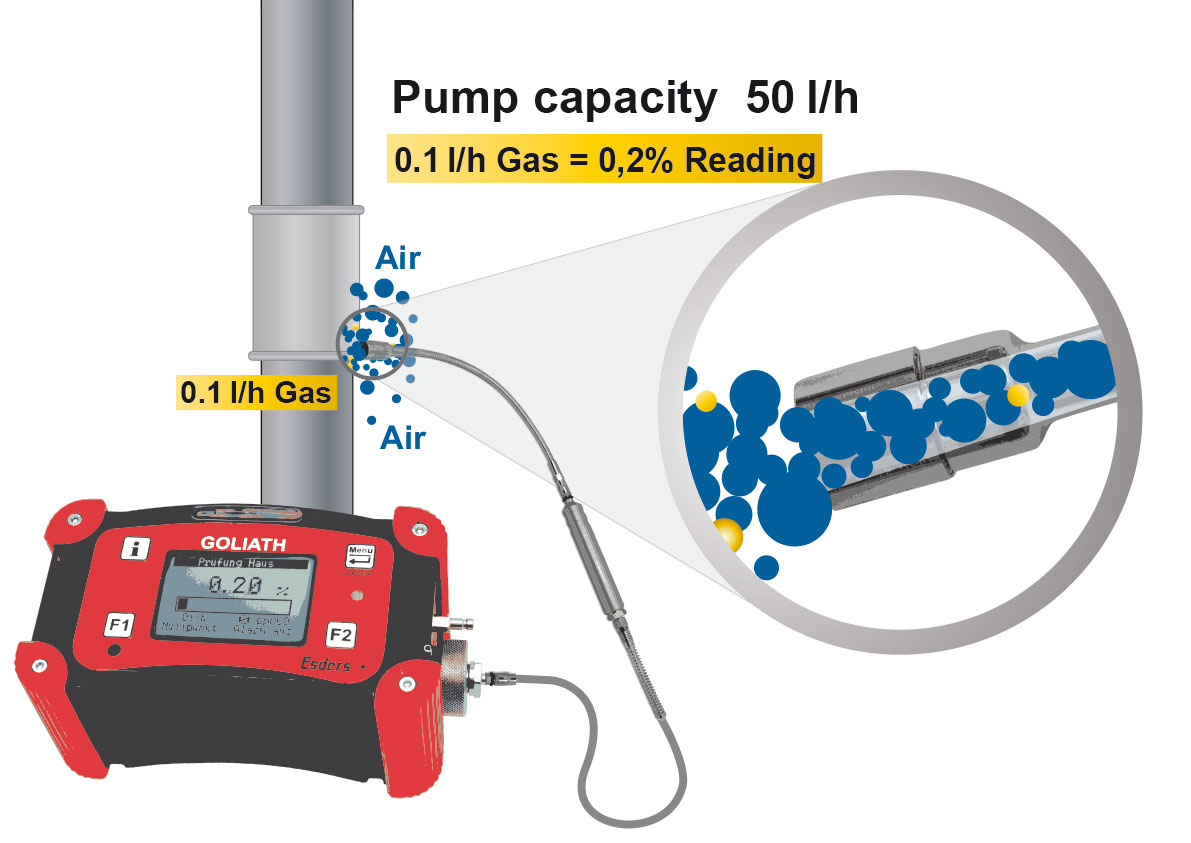

A pump device, such as the OLLI, sucks in escaping gas. As a rule, the pump capacity is higher than the amount of escaping gas. Therefore, the gas is diluted by air that is also sucked in. The stronger the pump, the stronger the dilution of the gas with air. The stronger the dilution, the smaller the indicated concentration.

In this illustration, the coloured display is intended to illustrate the mixing of little gas (yellow balls) with a lot of air (blue balls). Nevertheless, a relatively high concentration of 1 vol.% is displayed here, since the pump capacity of 10 l/h is not very high.

In this illustration, the same gas outlet volume is sucked in by a unit with a higher pump capacity. The 5 times higher pump capacity (50 l/h) ensures that 5 times more air is sucked in and thus the concentration is not 1 vol.% but only 0.2 vol.% or 2,000 ppm. For the evaluation of a gas leakage, the pump capacity of the measuring device must always be taken into account.

With regard to the inspection of industrial plants, a pump device is advantageous in practice. It can easily be used with an industrial probe.

The longer the probe, the longer the distance the gas has to travel, the longer the residence time should be depending on the pump capacity.

Example:

- We use an OLLI with 10 litres pump capacity and a probe of 1 m length. We set a dwell time of 3 seconds for optimal work.

- We use a GOLIATH with 50 litres pump capacity and a probe of 5 m length. The dwell time in this case is also 3 seconds.

But if we take a 5-metre probe in combination with the OLLI and a lower pump capacity, the retention time would increase to 15 seconds.

For more information on checking industrial gas installations, see our blog series Industrial Gas (Part I) and Leaks and Defects (Part II).

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)