Table of Contents

The basics of measuring ranges

The abbreviation LEL stands for Lower Explosion Limit and it corresponds to the concentration of a substance in the air above which there is a risk of explosion. The LEL of flammable gases such as methane, ethane, propane and butane is relevant for us. In this article we will limit ourselves to the LEL of methane.

Methane is measured in % LEL or % by volume (vol.-%). Methane is also measured in ppm (parts per million). The LEL monitoring serves the safety of individuals, because it can be stated that 100% LEL corresponds to 100% risk of explosion. When working in an area above the LEL, an ignition source in combination with oxygen can cause an explosion.

In Europe, we have set the LEL of methane at 4.4 vol.-%. Below this limit, ignition is not possible because the mixture of air and methane is too lean.

However, since measurements are only monitored at specific points, it is necessary to work at high safety levels. For example, if we measure in front of the body, the concentration in the room could increase significantly towards the ceiling.

Another reason for low alarm levels is that natural gas is always a gas mixture and contains other components besides methane. For example, propane and butane are often found in addition to ethane. Since these gases are explosive even at lower concentrations, the LEL of natural gas is usually slightly below 4.4 vol.-%.

For this reason, the alarm levels in Germany are set at 20% LEL or often already at 10% LEL for the first alarm.

When do we measure in LEL or % by volume or better in ppm range? What is the difference?

With % by volume we speak of one part per hundred and with ppm we speak of one part per million.

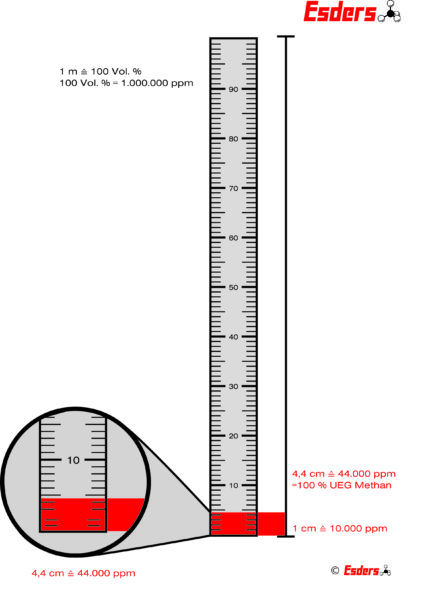

The measuring range in which we operate at ppm is therefore considerably smaller than the measuring range for a measurement in % LEL or vol.-%.

Smallest amounts of a gas like methane can be detected and displayed in the ppm range with a highly sensitive sensor (1 vol.-% = 10.000 ppm).

Since it is difficult to estimate values with many decimal places, e.g. 0.04 vol.- % or 0.008 vol.- %, the ppm measuring range is used for this purpose. In this case 0.04 vol.-% would then be 400 ppm.

To illustrate the measuring range we use a folding rule.

Comparison measuring range LEL (= UEG) versus PPM

We use 100 vol.-% as the measuring range for purging gas purity or pin pointing. If an empty natural gas pipeline is filled, it can be put back into operation when it reaches approx. 100 vol.-%. The aim is to achieve a complete natural gas atmosphere in the pipeline so that there are as few disturbances as possible for consumers when put into operation.

10,000 ppm (= 23 % LEL = 1 vol.-%) is measured in the LEL area for confined space entry. The reading is important for clearance measurement. This applies when entering shafts and cavities or when a gas smell is detected. From a measured value of 2.2 vol.-% = 50 % LEL, the room cannot be entered and working on a pipeline is prohibited.

The ppm range is generally used to detect the smallest concentrations. This is the case for inspecting pipelines or inspecting pipes in buildings. The measuring ranges are 0 to 1,000 ppm or 0 to 10,000 ppm depending on the type of device. The measuring range often depends on the type of sensors used in the device.

The 10 ppm test is for testing above ground (pipe network inspection), which is carried out with a carpet probe, for example, and measures highly sensible, lowest concentrations of methane in the ground in such a small measuring range that we can hardly represent it on a scale.

In a second blog post on the subject of LEL versus PPM, we will use a hands-on video to show that measurements in the ppm range have great advantages in pipeline inspection.