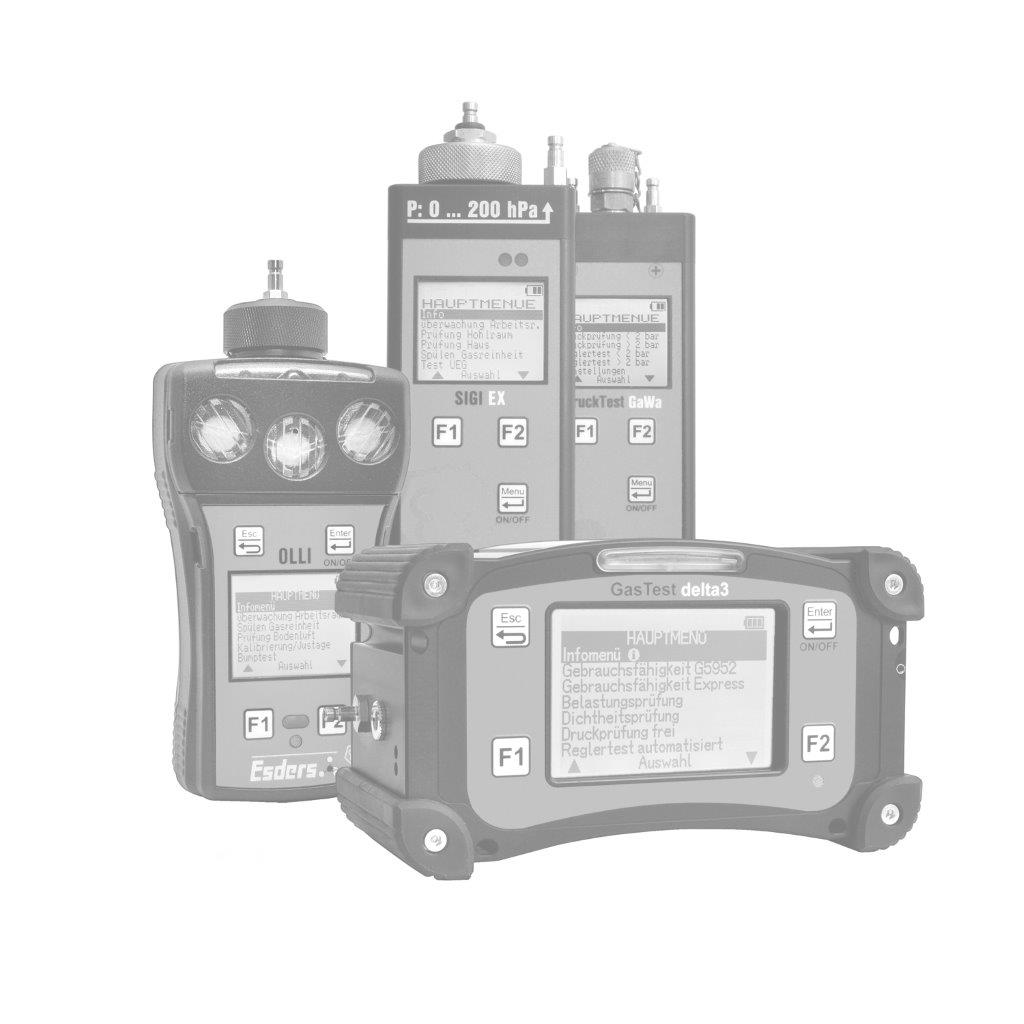

Effective implementation and documentation of gas system inspections in accordance with TRGI using TONI

The annual gas inspection is an integral part of responsible building maintenance. It is simple to carry out, but crucial for safety. Chimney sweeps often perform this task on behalf of homeowners or as an additional service. This work requires a keen eye and reliable documentation. This is exactly where Esders’ TONIs come into play. What is a gas system inspection and why is it so important? According to the Technical Rules for Gas Installations (TRGI), a gas inspection is

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)