As part of new construction, maintenance and repair activities, it often happens that gas house connections or mains connection pipelines have to be degassed and gassed. The excess gas was and still is usually released into the atmosphere via hoses or a blower. In view of the forthcoming EU Methane Regulation, venting will be prohibited in future in order to minimise climate-damaging methane emissions. Instead, controlled combustion of the excess gas is a much more climate-friendly option, as methane is converted into less climate-damaging CO2 and water (H2O) during combustion. A mobile gas flare can be used for this purpose, such as our Mobile Gas Flare S. This flare is very compact, can be set up in a short time without special tools and is therefore quickly ready for use. It meets the requirements of German DVGW Code of Practice G 404 (M) from July 2023. This article describes the situation in Germany. The situation may differ in other countries.

Annotated Extract from the EU Methane Regulation

We have created an annotated extract from the EU Methane Regulation relevant to the oil and gas sector with our thoughts, assessments and knowledge. Download it and find out more about measurement, reporting and verification requirements.

Decommissioning of house connection

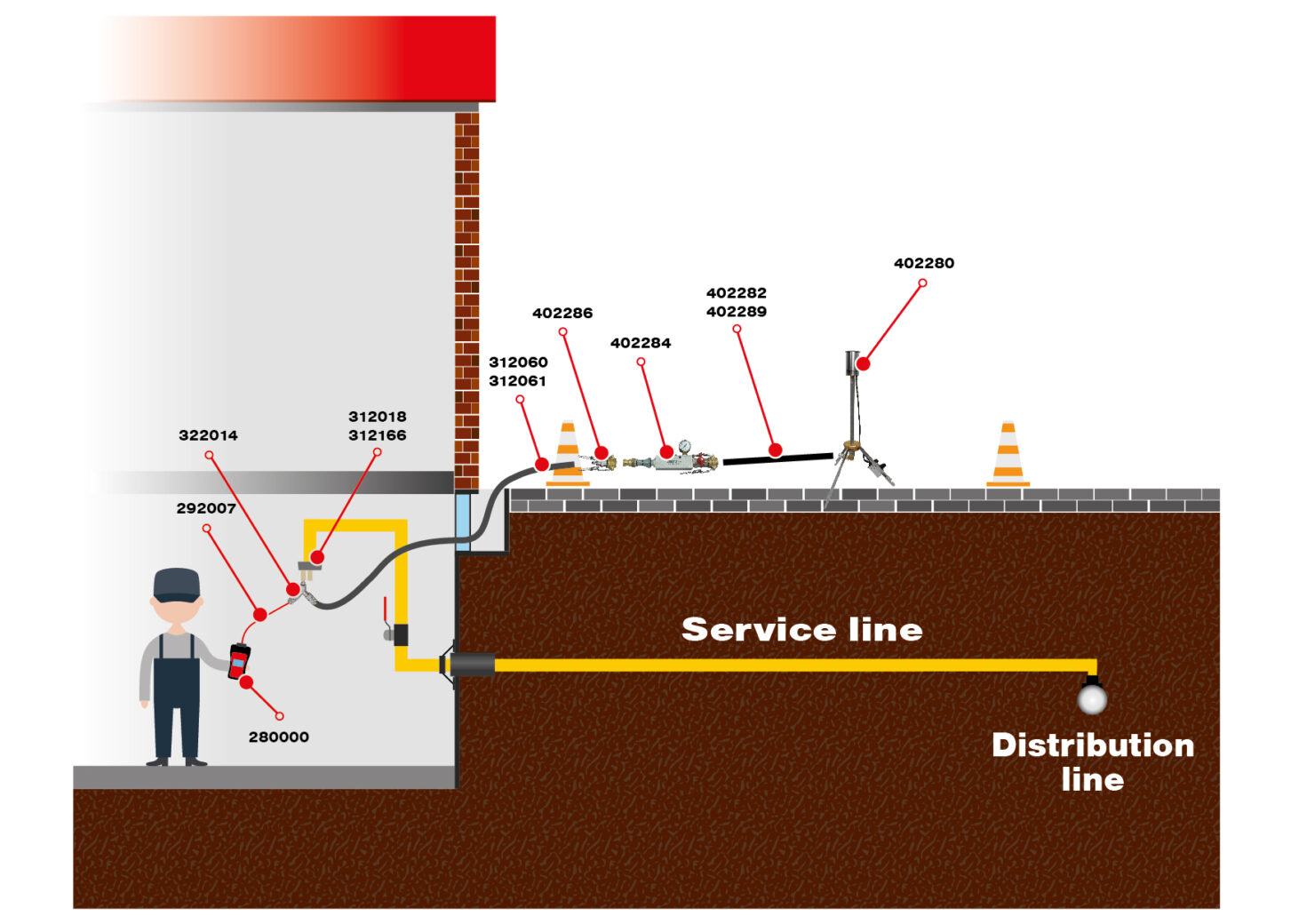

Existing mains connection that is in operation must first be degassed before starting maintenance work. To do this, the nearest valves in the distribution or supply pipeline to which the mains connection pipeline is connected should be closed. If necessary, a bypass pipeline must be laid beforehand so that other house connections are not unintentionally disconnected from the gas supply. Usually, a connection to the mains connection pipeline is made from the inside of the house concerned afterwards or beforehand. There are various options for this within the house installation.

It is quite common to dismantle the gas meter and then use suitable adapters on the gas meter fitting. This makes it possible to connect two devices at the same time for both single-pipe and twin-pipe meters. For single-pipe meters, the test cap is fitted to the meter connection piece with the meter seal inserted. The seal prevents unintentional gas flow into the internal installation. A Y-adapter is then connected to the external coupling of the adapter and the connecting hoses are connected to this in turn. This means that a gas analyser can be connected in the house to measure the concentration in the pipeline during the expansion process and – outside the house – the Mobile Gas Flare S can be connected to burn the excess gas. The benefits of this in terms of reducing methane emissions can be seen below when gassing the mains connection line. The closed fittings in the house (e.g. meter tap and/or main shut-off device) can now be opened and the excess gas can be burnt in a controlled and safe manner until the pipe is depressurised. A small amount of residual gas often remains in the pipe or is flushed out with air.

Commissioning of house connection

After work on the mains connection has been completed or new lines have been successfully tested in accordance with german DVGW G 459-1, they must be gassed again. The same set-up can be used for this as for the degassing described above. One advantage of this variant is that the gas purity of the mains connection pipeline can be determined almost directly at the end of the line during the purging process and not at the end of the hose, blow-out unit or gas flare, as was previously the case. This means that unnecessary methane emissions can be avoided because the gas purity is determined at an earlier point in the entire set-up and the purging process can therefore be completed more quickly. Depending on the length of the hose to the flare or to suitable measuring points (e.g. our connection strip), this can mean considerable potential savings. The volumes to be saved by a single mains connection line are small in the case of house connections. However, as soon as these small quantities of such a measure are summarised over many applications, e.g. in an annual balance, a considerable emission avoidance potential is created.

The use of the Mobile Gas Flare S described above, including measuring the gas concentration in the building, is worthwhile not only from an ecological but also from an economic point of view. If company guidelines and local regulations permit, such activities can be carried out by a single person. Previously, two people were always required to measure the gas concentration at the blow-out unit and to control the purging process at the corresponding fitting (e.g. in the building). In times of a shortage of skilled workers, which affects the gas industry just as much as other sectors, this is certainly an aspect that should be considered. In addition, the procedure described also makes sense from a safety point of view, as the gas concentration is measured at a sufficient distance from the gas flare. As a result, there is no risk of physical injury (burns, noise damage).

The flow rate and the amount of methane flared off during the flushing process (degassing / gassing) can be recorded and measured using the devices and accessories shown below. The connecting hose and an adapter T-piece are also required for this. In particular, the amount of methane recorded must be reported to the relevant authorities in future as part of the forthcoming EU methane regulation. Details on this are currently being developed at DVGW level and are expected to be published at the end of this year.

Download test report sample v-measurement now

The test caps serve as a connection piece for the gas flare and the gas measuring device at the meter connection on single-pipe or two-pipe meters.

For single-pipe meters, this adapter is mounted on the outer coupling of the test cap.

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)

.jpg?width=100)