Table of Contents

In our blog post from 12 March 2020, we first discussed vehicle-based gas leak detection using gas detection vehicles and pointed out the special features of this type of above-ground inspection of buried gas pipelines.

At that time, the new versions of DVGW Standards G 465-1 (A) and G 465-4 (M) had been published shortly before, and vehicle-based inspection had been included in them for the first time and thus declared state of the art.

The DVGW research project on the evaluation of new measurement methods for pipeline inspection in gas networks (EvaNeMeL), which was already mentioned in the first blog post, is now complete, so we would like to focus more on this topic again.

New findings of the EvaNeMeL research project

As part of the project, a total of five vehicle-based systems were investigated and evaluated, including our GasCar Laser HUNTER, in addition to other device technologies.

All systems work according to the TDLAS principle (Tunable Diode Laser Absorption Spectroscopy) for the detection of methane. This laser method has the advantage that it is very sensitive at the specific measuring wavelength of methane (λ = 1.65 μm) and has no relevant cross-sensitivities to other gases in the atmosphere, e.g. exhaust gases from other cars.

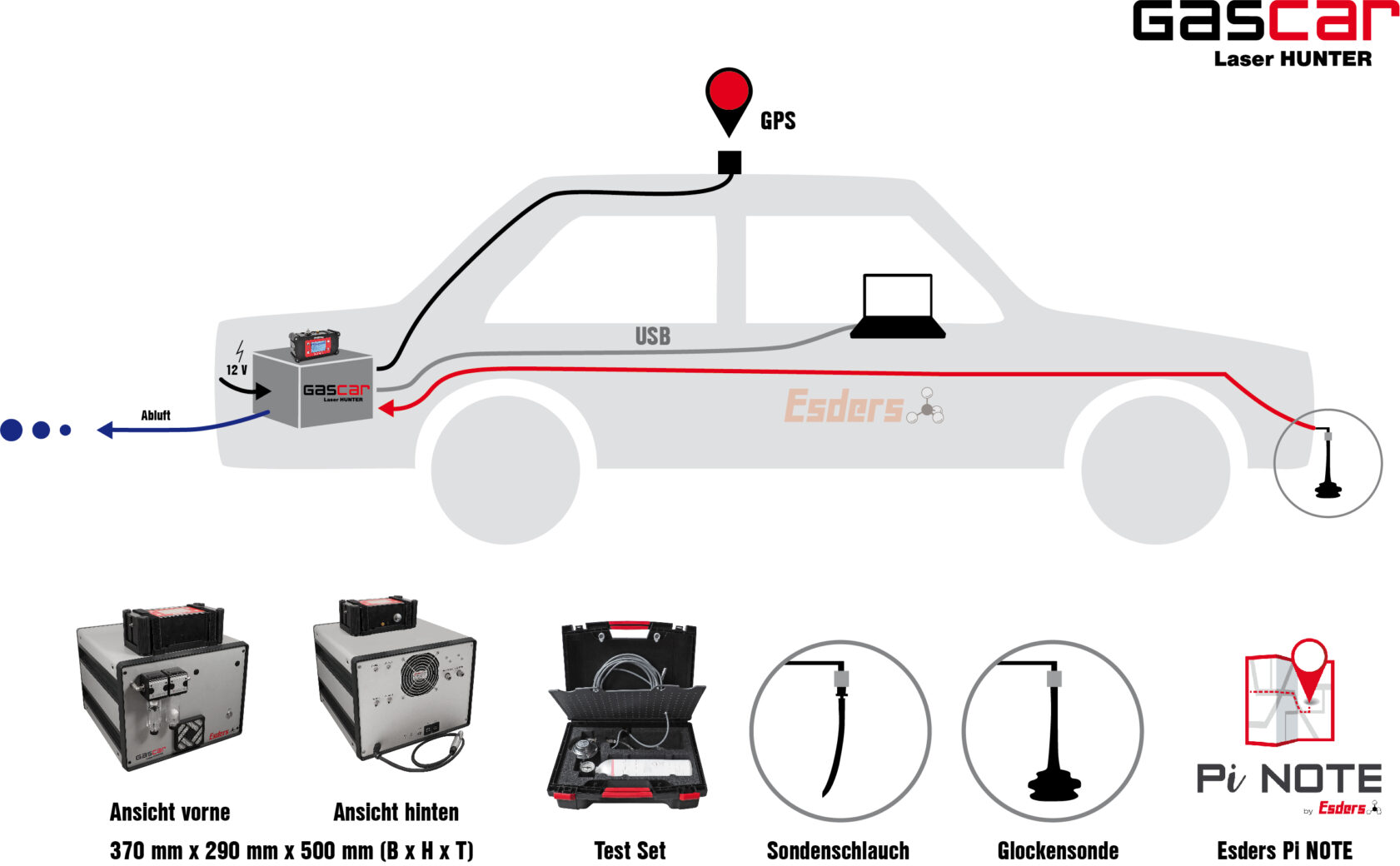

The five systems were again divided into two categories. Three of the five systems, including our GasCar Laser HUNTER, are already covered by the current G 465 regulations of the DVGW. They work with probes mounted over the entire front of the vehicle to suck in the gas flow. This is evaluated by a device, which is usually located in the rear of the vehicle, and the result is transmitted to a notebook with specific software.

Structure of GasCar Laser HUNTER

The other two systems represent a new approach and record the wind speed in addition to the gas flow. The software then calculates the probable position of a leakage from the combined measured values. These systems are not yet covered by the applicable DVGW regulations.

All systems were compared in various measurement tests using a conventional gas detector, which carried out the test with a hand-held measuring device and carpet probe, as a reference.

In addition, laboratory tests were carried out on sensitivity, cross-sensitivity and handling. The results will be published in a technical article in ewp at the beginning of next year.

Without prejudging the technical paper, it can be stated that the concerns already mentioned in the first blog post were confirmed in principle. In practical terms, this means that there are the following limits to the use of vehicle-based pipeline network inspection.

- Due to the higher speed, the time for sucking in the gas sample is much shorter. This means that in the worst case, leaks can be ” missed ” without detection.

- Especially in the case of sealed surfaces, the gas often only escapes at one point (e.g. at the gutter). As a result, a homogeneous gas cloud often does not form above the outlet point, which makes detection considerably more difficult.

- Parked vehicles at the roadside hinder proper inspection. Parts of the pipeline that cannot be inspected must therefore be inspected later by driving over them again or by conventional methods.

Conclusion

In conclusion, vehicle-based inspection of buried gas pipelines can be a useful supplement to conventional inspection if certain general conditions are met.

These include, for example, a reasonably passable route outside built-up areas to avoid the problem of parked cars and no excessive wind during the inspection.

However, one advantage of the vehicle-based method is that it can also be carried out at night, which is not possible or not done with traditional inspection.

It is also pleasing that the research project provides at least a general answer to the frequently asked question about the recommended inspection speed. Depending on the traffic situation, a speed of 15 km/h to 30 km/h was found to be suitable.

The results of the research project, particularly with regard to detailed information on the conditions of use (e.g. inspection speed) and requirements for the measurement technology, are to serve as a basis for revising the existing G 465-1 (A) and G 465-4 (M) standards.

However, a new edition of these two sets of rules is probably not expected until later next year, possibly not even until 2024.