Table of Contents

Methane as a greenhouse gas

Climate protection and climate neutrality are probably the greatest challenges of our time. Since the beginning of industrialisation, global warming, caused by the greenhouse effect, has affected people and the environment in many different ways. The main causes of this are emissions of greenhouse gases, such as carbon dioxide, nitrogen oxides or methane, which lead to a heating of the global climate.

The contribution of carbon dioxide to climate change is indisputably the largest and a significant reduction of CO₂ emissions must therefore be achieved in the coming years. But a further reduction of methane emissions is also the goal of many international and national organisations.

Although methane has a smaller share in the atmosphere than CO₂, it is significantly more harmful (more effective as a greenhouse gas) than CO₂. There are currently many international approaches to reducing methane emissions in different parts of the oil and gas supply chain.

For example, the European Union published the EU Methane Strategy in October 2020 with the aim of reducing methane emissions in the energy, agriculture and waste management sectors. The focus of the measures is on energy and a reduction of methane emissions along the entire supply chain.

Global and national initiatives to reduce methane emissions

Global initiatives such as the Oil and Gas Methane Partnership 2.0 (OGMP 2.0) are also intended to reduce methane emissions. German energy suppliers also participate in these initiatives, e.g. to contribute to the global reduction of methane emissions at local or national level.

The OGMP provides uniform specifications for the systematic recording and logging of methane emissions and develops measures and strategies to prevent and reduce emissions. Typically, these measures are in the area of transport and distribution networks.

Parallel to these global, international initiatives and associations, national initiatives and projects are forming. One focus of the EU methane strategy, for example, is the avoidance of methane emissions along the gas supply chain. For this focus, the German DVGW initiated a research project on the topic “Preparation of a guideline with measures for the technical reduction of methane emissions in the gas distribution network” (DVGW ME-Red DSO). The currently published DVGW Code of Practice G 404 also recommends gas flares as an effective tool for reducing operational methane emissions. Our mobile gas flares meet all the requirements of the technical bulletin.

In the final report of this project, various measures and technical solutions are examined with regard to their advantages and disadvantages, their feasibility and the cost-benefit ratio. Methane emissions within the distribution grid operation are divided into their causes.

In detail, these are intrinsic emissions (e.g. technical leaks, smallest leakages, permeation, etc.), operational emissions (due to blow-out processes, e.g. during decommissioning/commissioning) and emissions during malfunctions (damage, dredging damage, etc.).

Reduction of gas blow-off and flaring

In the area of operational emissions, there are already methods for reducing blow-off quantities that have become established and are frequently used in recent years. One suitable solution is gas flaring.

Flaring replaces the pure blowing out of natural gas and experiences its effect through the conversion of methane into carbon dioxide (CO₂). Methane is far more harmful to the climate than CO₂ and thus contributes more to the greenhouse gas effect than the same amount of CO₂ (25 times more harmful to the climate).

Thus, for environmental reasons, it is better to burn excess quantities of methane than to simply blow it out into the atmosphere. Moreover, blowing out natural gas or methane is also not recommended for occupational safety reasons.

There are standards and guidelines in Germany that specify technical requirements for the blow-off process, e.g. the height of the blow-off pipe (DVGW G 465-2). But under special circumstances, it is still possible in an emergency to endanger persons by a gas cloud or an ignitable mixture in the area of the work site. Provided that the gas to be blown out is completely burnt off directly, such a hazard is excluded.

Technology required for methane flaring

We have been offering a technical solution for flaring gas for many years.

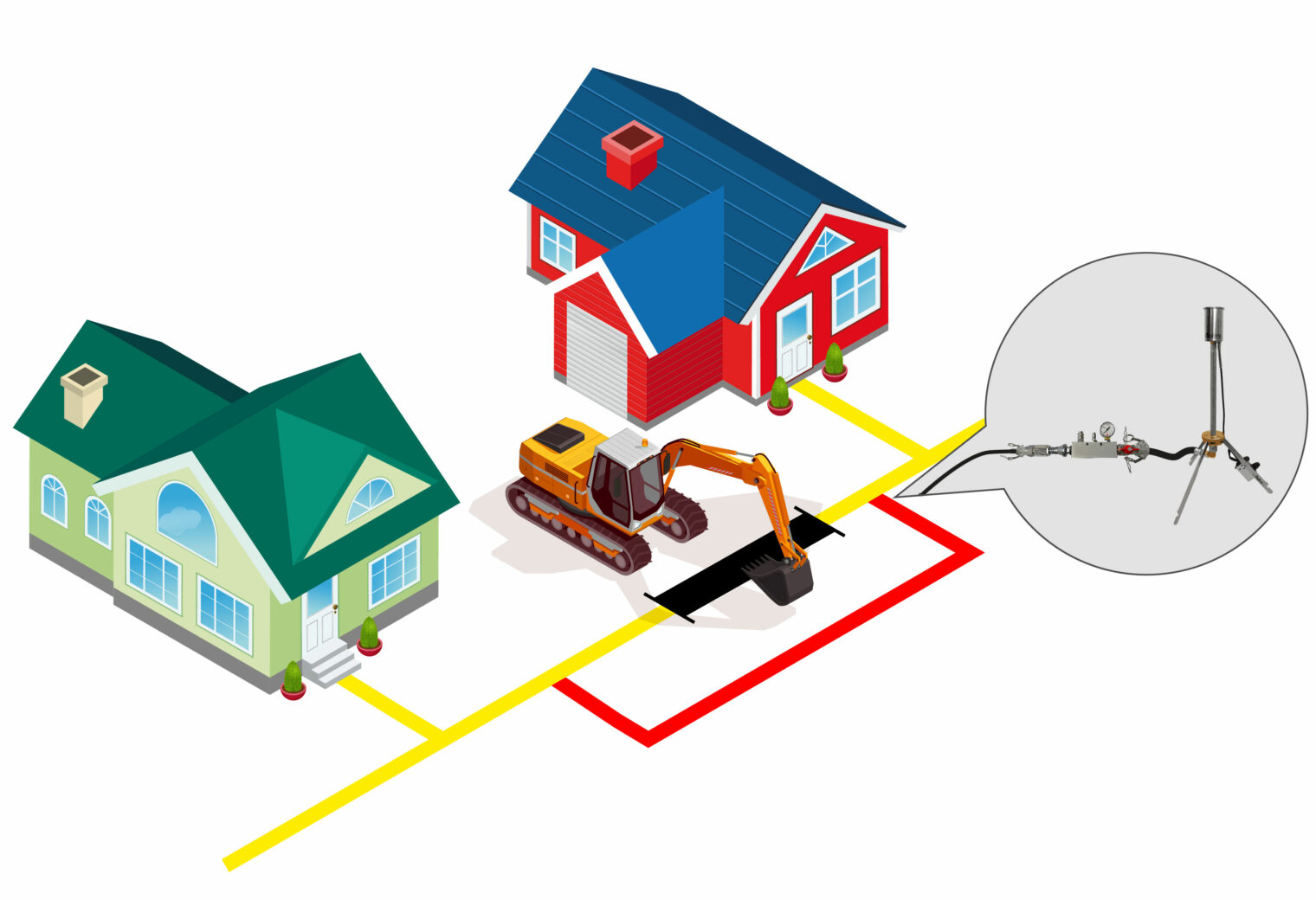

With the Gas standpipe without blow-off pipe commissioning and decommissioning of pipelines can be carried out in all pressure ranges from atmospheric pressure up to 20 bar. The blowing off of gas is possible with the gas stand pipe, as is flaring. However, for reasons of environmental protection and occupational safety, flaring is recommended.

The final report of the ME-Red DSO also identified flaring with the gas test stand pipe as the “top measure” and analysed it in detail (tripod flare for high-pressure range).

The authors of the final report concluded that although a gas flare was a suitable measure for reducing methane emissions, the cost-benefit ratio currently only allowed it to be used sensibly in the high-pressure range.

For the low- and medium-pressure range, there was a lack of cost-effective technologies that are in reasonable proportion to the significantly lower methane quantities or the significantly lower methane reduction potential in these pressure ranges.

Mobile Gas Flare S for the low and medium pressure range

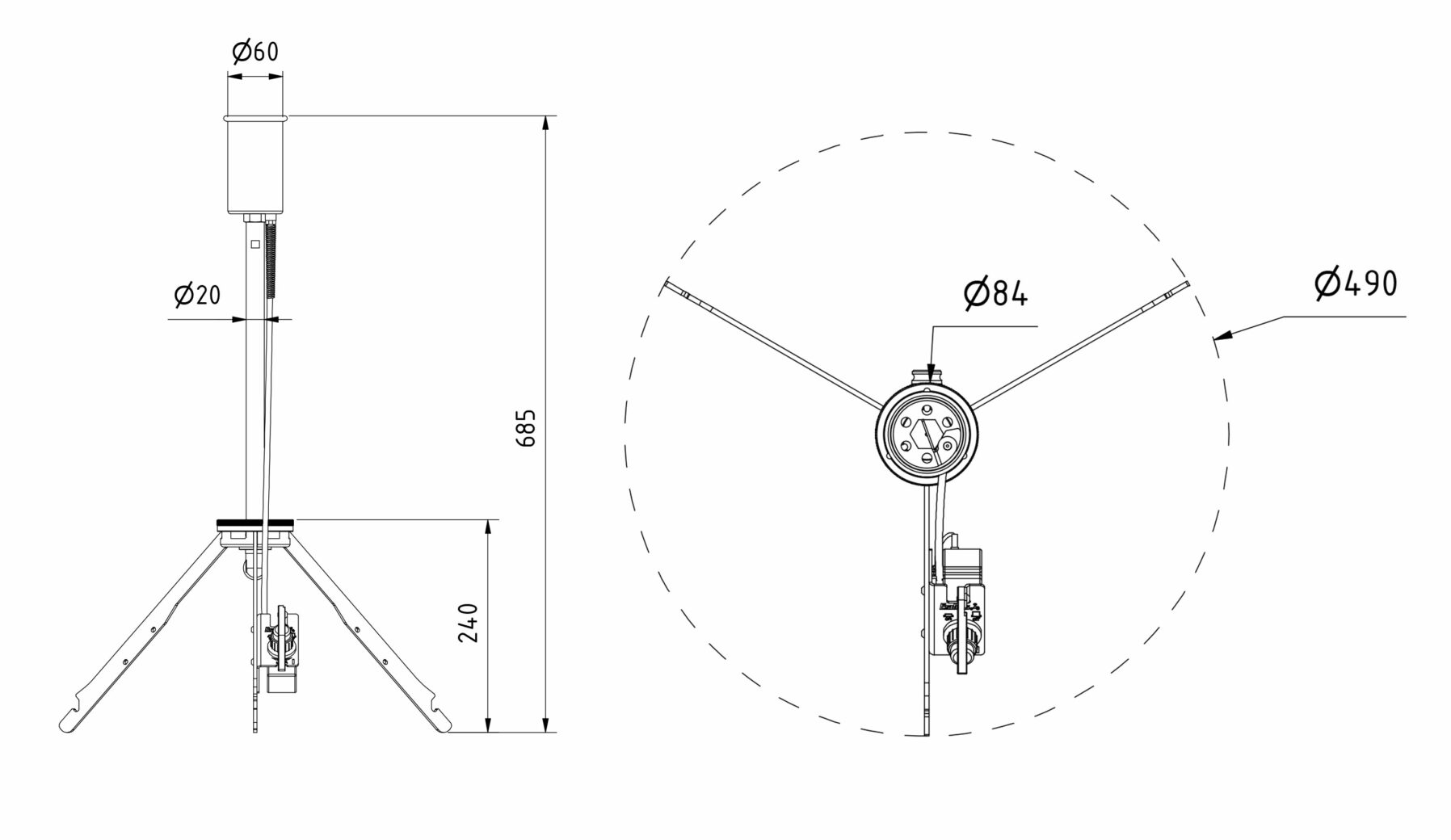

We have therefore developed the Mobile Gas Flare S especially for the low-pressure and medium-pressure range. We offer a cost-effective, compact solution that is used purely for flaring gas.

The device is ready for use in a few minutes and is thus a suitable measure to avoid blow-out quantities in the area of service line connections as well. Especially in the case of connections to new houses, the volumes to be saved in a single connection pipe are small, but as soon as these small quantities of such a measure are added up over many applications, e.g. in an annual balance, a considerable emission avoidance potential is created.

With the help of the Mobile Gas Flare S, a significant contribution to the reduction of methane emissions in the gas distribution network can be achieved during the commissioning of service line connections alone, through the use of low investment costs and low labour input per measure.

The Mobile Gas Flare S has a fixed operating range from 1 bar down to a few mbar above atmospheric pressure. In this pressure range, the gas is burnt in an environmentally friendly, low-pollutant and almost complete manner through optimised combustion.

The volume flow depends on the operating pressure and is in the range of approx. 8 Nm3/h at 1 bar inlet pressure. An integrated (continuous) ignition system guarantees stable combustion and also ensures adequate occupational safety, as no personnel have to go near the escaping gas to ignite the flame.

The operating range of the Gas Flare S is limited to a maximum of 1 bar, as factors such as flame pattern, sound level and stable combustion would no longer be optimal at higher pressures. However, the inlet pressure may be up to approx. 10 bar and is then reduced by the connection accessories supplied with the Gas Flare S. This means that the Mobile Gas Flare S can also be used in the high-pressure range.

Additional areas of application for the Mobile Gas Flare S are possible in combination with other “top” measures from the DVGW ME-Red DSO final report.

When using a mobile compressor for decommissioning, a residual gas quantity with pressures in the range of 700 mbar always remains in the pipeline for technical reasons. Reducing the operating pressure before decommissioning also leads to a residual pressure in the pipeline, which must be dissipated in another way. As a third measure, the reduction of the pipeline section to be blown out is a common measure for the reduction of operational emissions.

For all three measures mentioned, a downstream application of a mobile gas flare is possible in order to flare off residual gas quantities at partially reduced pressure in a clean and environmentally friendly way.

These possible combinations of measures are not all explicitly mentioned in the final report, but in our opinion, they make sense and are at least recommended. Considering set-up times in the range of minutes for the Mobile Gas Flare S, large emission reductions can be achieved with little effort.

Several DVGW worksheets are currently being edited, e.g. DVGW G 465-2 and a new information sheet on measures to reduce methane emissions in the gas distribution network. We at Esders GmbH recommend that gas flaring in the area of operational emissions be given increased focus and included in relevant worksheets as a suitable measure for reducing methane emissions in the gas distribution network. Flaring not only contributes to environmental protection, but also to occupational safety. With our new product, the Mobile Gas Flare S, we are making a further contribution to climate-neutral distribution network operation and providing technical solutions for climate protection and occupational safety.

Download an asset on flaring methane

Are you interested in reducing methane emissions? Then you should definitely download this asset on how flaring methane reduces emissions. This asset explains how the Mobile Gas Flare is the best alternative to blowing off and releasing.

By downloading this asset, you will gain valuable knowledge about the flaring times.

.jpg?width=100)