This blog post on the basics of pressure testing on water pipelines is an introductory article and also suitable for students and non-experts. For experienced professionals, the next articles on successful water pressure testing will go further into detail on the various methods and their application in everyday work.

Our water distribution system distinguishes between service and drinking water pipes. In the following we will concentrate on the drinking water pipeline systems.

The water flows through our pipes at a certain pressure. For the quality and purity of our drinking water it is necessary that the water does not remain in the pipe for long. To make our water as clean as possible, not only pumping stations and pressure boosting stations are used, but also the material of the pipe is taken into consideration. There are numerous requirements and technical rules for the materials to be used, which are defined in the European standard DIN EN 805 and according to DVGW W 400 water distribution systems. These describe the generally recognised state of the art in Europe and Germany.

Supply pressure

The network provider determines which pressures are operated. A pressure of 3 bar should be sufficient to supply a single-family house with water in the rather flat Emsland region in the northwest of Germany. The pipelines usually have small nominal diameters and must withstand an operating pressure of at least 10 bar. But what about hotels with higher floors or high-rise buildings in large cities? Here, higher pressure must be applied so that sufficient water pressure is also guaranteed on the upper floors.

In hilly areas, the pressure in the supply line is quite different from the situation here in Emsland. While the pressure in this area is lower and does not exceed 10 bar (the supply pressure in the distribution system in the municipal area is much lower at 6 bar), the network in hilly areas is operated with up to 15 bar. Accordingly the pressure tests are also carried out – depending on the material – at higher pressures.

For the house connection, a pressure reducer is inserted into the house service line to adjust the pressure of the supply line to the required pressure of the service line.

Flow velocity

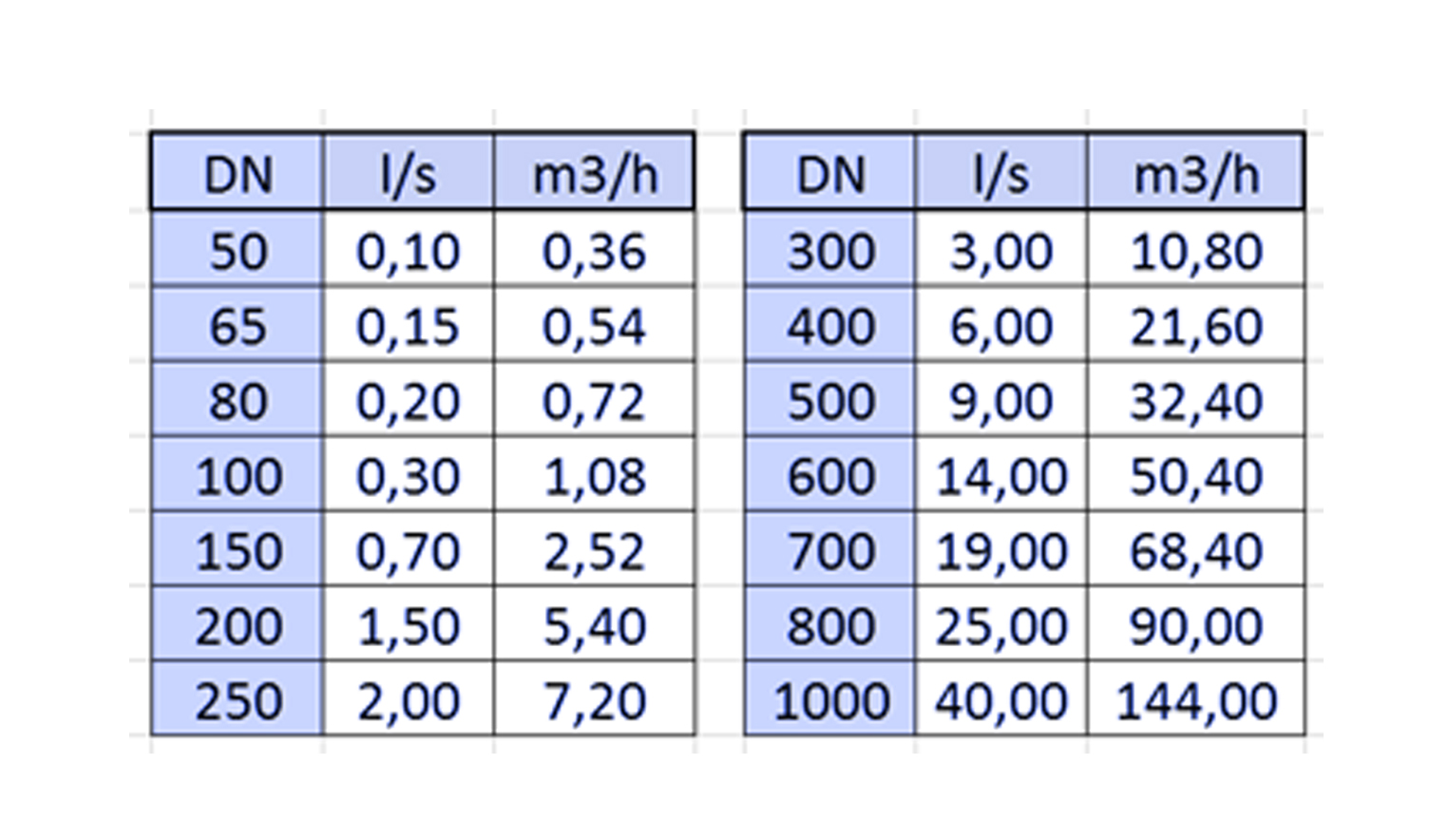

The flow velocity of the water is also specified in the DVGW rules and regulations with an average hourly flow rate of 0.005 m/s or more (Technical Rules for Water Distribution Systems (TRWV), Worksheet W 400-1). The lower the flow velocity in the pipe, the longer the dwell time of the water at low withdrawals. Under certain circumstances this can lead to bacterial contamination. For this reason rarely used pipes should be flushed.

What is a pressure test on water pipelines?

A pressure test on a water pipe is a method of testing newly fitted pipelines for leak tightness. The water provider is responsible for distribution lines in Germany. The German TRWV applies there. Pressure tests on water pipes are carried out properly according to the technical rules of DVGW W 400-2. A leak is bad for two reasons. Firstly, a valuable resource is wasted and secondly, it can contaminate the drinking water. Leak tightness is a prerequisite for acceptance and commissioning of the pipe.

When is a pressure test carried out and what procedures do exist?

According to DVGW W 400-2 (Construction and testing of drinking water distribution systems), the following applies in general: Every drinking water pipeline must be subjected to a pressure test after it has been installed! This also includes recommissioning after pipe rehabilitation.

Each pressure test procedure must be carried out in three steps (DIN EN 805):

- Preliminary test

- Pressure drop test

- Main test

Requirements for a successful pressure test

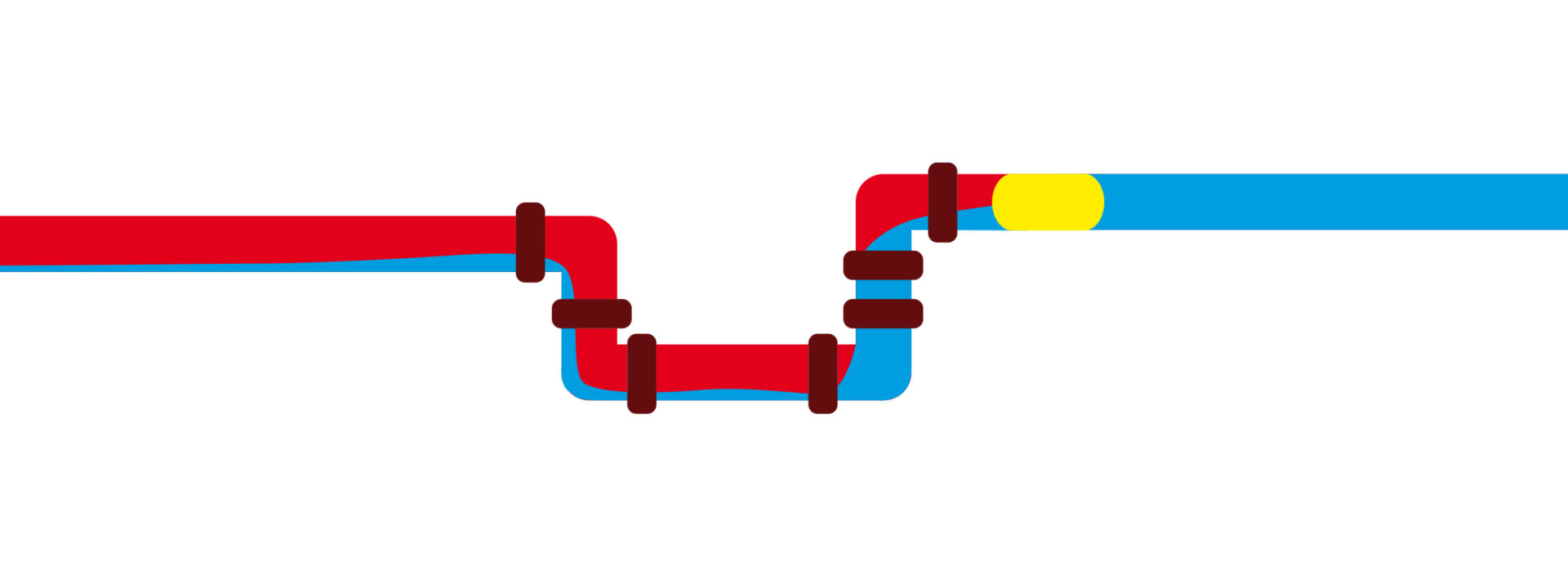

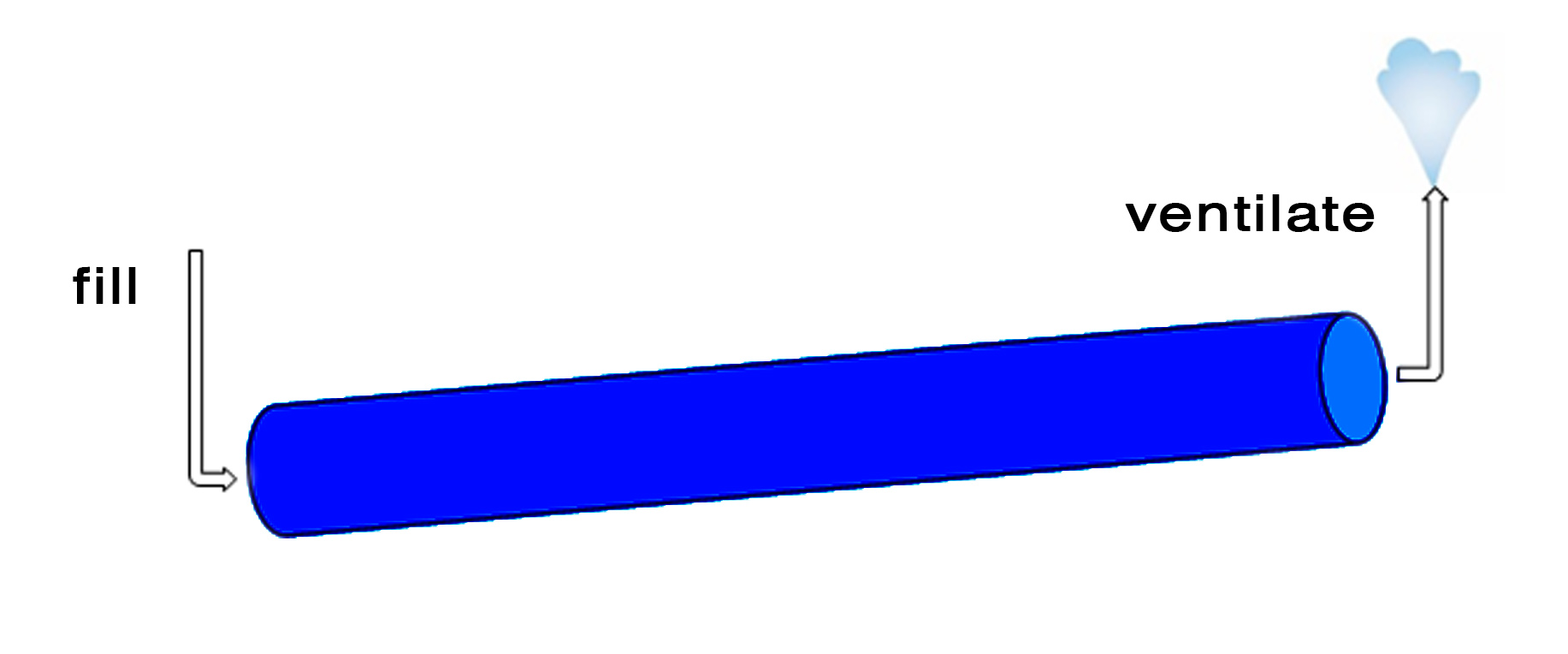

The pipe section to be inspected is filled with drinking water and vented. The basic prerequisite for assessing the tightness of a pipeline is sufficient venting. This cannot always be achieved by flushing with water, so pigging should be carried out in these cases. For example, pipelines that are laid using trenchless methods have proven to be problematic. This method of laying can result in the pipe being installed not only horizontally but also in an arc. In the higher sections the air cannot be safely removed by flushing.

What is pigging?

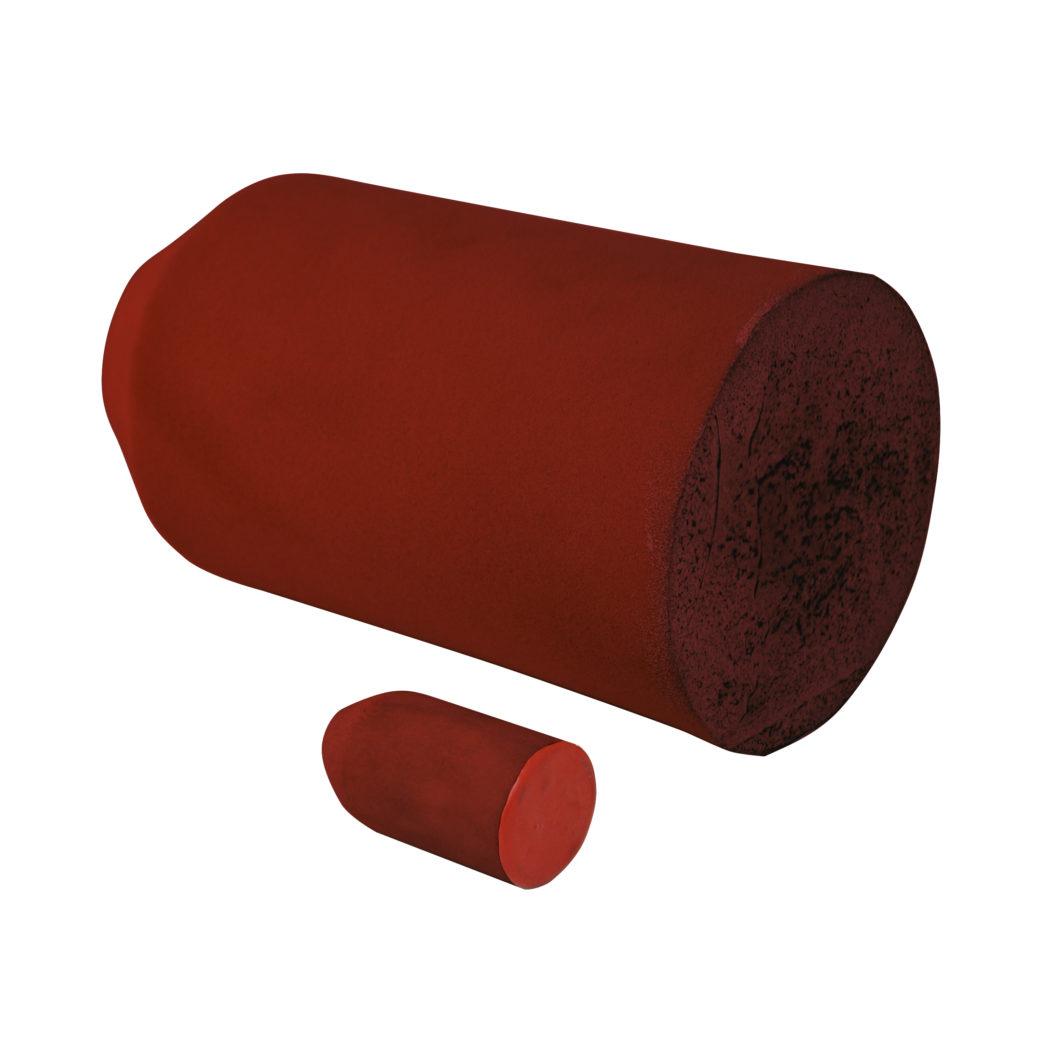

The pigging procedure is the solution for an air-free pipeline. The pig (pipeline inspection gauge) is a synthetic body, which lies tightly against the wall, is pushed through the pipeline with the medium water. Due to the space-filling closure up to the pipe wall, any air present is also pushed through the pipe and can escape at the other end of the pipe. The pig is also removed from the pipeline at this location. The pipeline is then completely filled with water and almost free of air. Only very small residual amounts of air, e.g. at pipe connections, can remain.

Example of pigs

An “air-free” filled pipeline is crucial for a successful pressure test!

What must be taken into consideration?

- any kind of foreign matter must be removed from the pipeline before testing

- the pipeline is to be filled with open valves and sufficient venting

- fill only with “drinking water quality

- simultaneous addition of disinfectant is possible

- always fill from the low point to the high point!

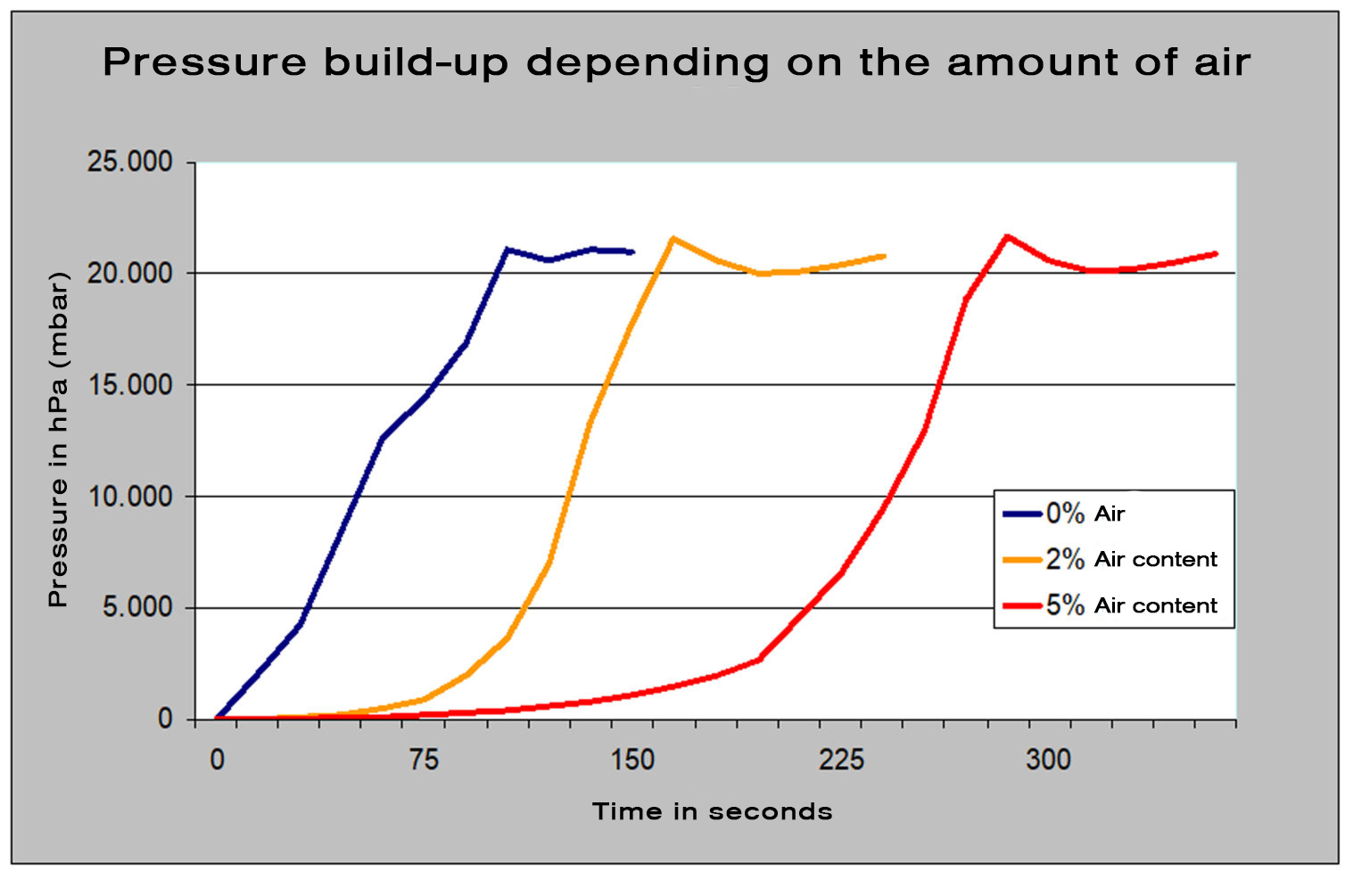

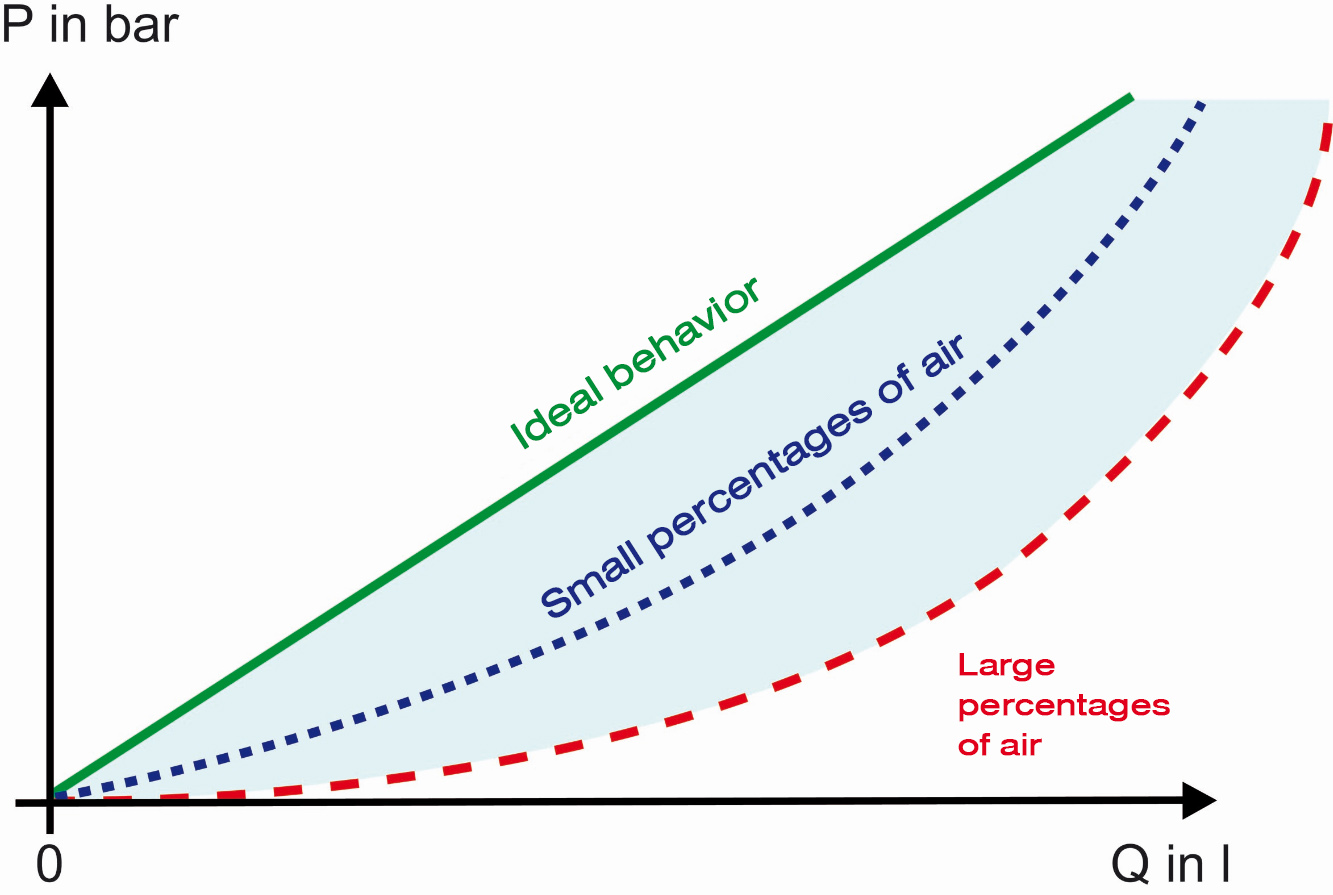

A poorly vented pipeline can already be detected in the pressure build-up phase. For this purpose, we have carried out a test with the MPP on our test track in Haselünne (with 0%, 2% and 5% air content in the line). The more air in the pipe, the longer the pump needs to build up pressure and the more bulbous the curve in the diagram looks.

It is obvious that the air in the lower pressure range has an extreme effect and the pressure build-up is delayed by minutes. In most cases this is not due to a defect of the pump, but to a poorly vented pipe. Once a pressure of 10 bar has been built up, there is hardly any difference.

You can see how well a pigging works in the video.

The pipe simulation is made of PVC so that the filling and flushing to remove the air and the pig is visible.

In the front area there is a section of the pipeline as it occurs with a culvert.

In the rear area there is a wavy section as it occurs in trenchless pipe jacking.

Let us solve your pressure measurement challenges together.

You have learned the basics of water pressure testing and seen how complex and important this task is. Rely on our expertise, as a professional in the field of pressure measurement technology. We offer not only in-depth knowledge, but also high-quality products and seminars to help you perform your tasks efficiently and safely. Contact us today and let’s work together to ensure your water pressure testing meets the highest standards. Click here to get in touch with our technicians!