Many of our handheld devices work with different sensors to measure gas and pressure. We will explain these different sensor principles here:

Infrared sensor (IR-sensor)

An infrared sensor measures wavelengths that are not visible to humans because they are below the red light visible to humans. The measurement is used to detect heat and movement of bodies and objects. The detection is non-contact.

The function enables measurements of temperature without contact, wireless data transmission, for example for thermal imaging cameras and movement in the dark. Well-known everyday products that include infrared sensors are remote controls and motion detectors.

Infrared sensors that are suitable for measuring gases operate according to the measuring principle of non-dispersive infrared absorption (NDIR). They are also used, for example, to analyse exhaust gases from combustion engines.

Our measuring devices (GOLIATH and OLLI) are equipped with IR sensors that work according to the NDIR principle. Usually this sensor is designed for a target gas, to which it is sensitive and displays the concentration, e.g. methane, propane or carbon dioxide. A Dual-IR sensor is able to measure two different gas components at the same time, two sensors for two different gases are placed in one sensor housing. In the OLLI, the dual IR sensor simultaneously measures combustible gases (e.g. methane) and CO₂.

Laser sensor

In a laser sensor, laser diodes emit light pulses or beams. These are reflected by an object to be measured and are then returned to the sensor. The distance between the sensor and the measured object is measured by this light reflection. In addition to distance, a laser sensor can also detect distances and positions without contact. This sensor has a long range as well as a high resolution and accuracy.

The laser sensor is used, for example, in mechanical and plant engineering, in the chemical industry, in road construction, in the automation industry, in storage and packaging technology and in leakage detection.

One of our mobile laser measuring devices is the ELLI. The sensor technology used in the device (adjustable diode laser – absorption spectroscopy) serves to detect methane leaks or methane accumulations and can detect methane even in very low concentrations. The Esders Laser Leak Indicator ELLI is mainly used in remote sensing. The laser sensor makes it possible to detect methane from greater distances of up to 30 metres. How the laser works is also explained in our blog post Remote Detection of Methane – Laser Infrared Spectrometry.

Heat tone sensor

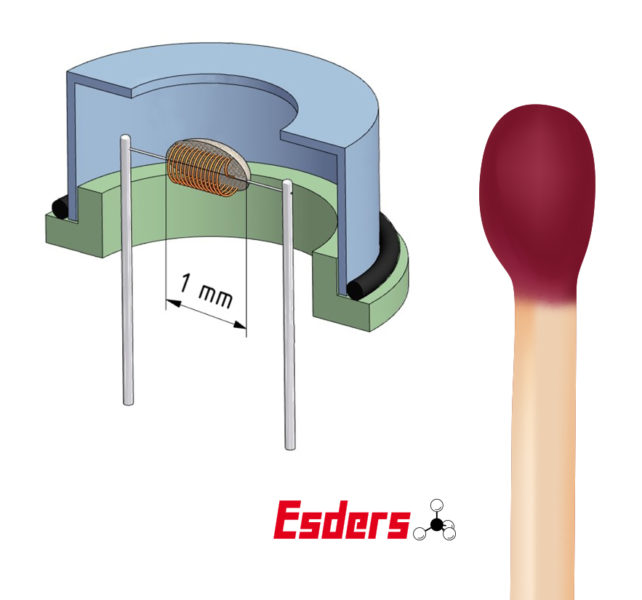

This sensor works according to the measuring principle of catalytic combustion and is used in measuring instruments for explosive gases and vapours. The measuring principle consists of a bridge branch with two sensors composed of an active and a passive pellistor (gas sensor) in a platinum spiral. This is called a Wheatstone bridge circuit.

This principle includes the detection of flammable substances without including the ambient temperature in the result. The small platinum spiral is surrounded by a ceramic catalyst and is heated by a controlled current to several hundred degrees, which heats the active pellistor to about 450 degrees Celsius. The catalyst causes a reaction of combustible gases with oxygen below the actual ignition temperature. This reaction is a flameless combustion that generates heat. The heat changes the resistance of the platinum wire and can therefore be measured and displayed.

Note: Oxygen (air) is required for the measurement. At concentrations > 5% (methane calibration) accurate measurements are not possible due to the lack of oxygen.

A characteristic feature of this measuring method is the reliable indication of all combustible gases. However, it must not be neglected that the display is only correct for the gas to which the instrument has been calibrated. For example, an instrument calibrated for methane will display propane and butane from the lighter. However, the display will never show the correct concentration in volume % or % LEL.

The properties of the measuring method of catalytic combustion or heat tinting can be easily recalled when thinking of the automotive catalytic converter. Even with the autocatalytic converter, unburnt hydrocarbons can only be oxidized if there is sufficient air. Therefore, the air concentration is measured by the so-called Lambda sensor. Just as with the autocatalytic converter, the sensor’s catalyst can be poisoned by certain substances.

In addition to leaded vapours (formerly comparable with leaded petrol), silicone and halogens are also to be mentioned here.

A great advantage of this sensor is the robustness and accuracy we need for measurements in the LEL range. A typical field of application is: measuring danger – LEL. We use a heat tone sensor in our sensor arrays.

Electrochemical sensor

This sensor consists of at least three electrodes: a working electrode, a counter electrode and a reference electrode. These three electrodes meet liquid electrolytes in the housing.

The measuring principle is based on gas passing through a membrane to the working electrode. The membrane is permeable to gas, but not to the electrolytes. This process triggers an electrochemical reaction. Either the working electrode releases electrons, in which case an oxidation occurs, or it accepts electrons, in which case a reduction occurs. The flow of electrons generates electric current, which is proportional to the gas concentration and can be measured. The electrochemical sensor provides high sensitivity and easy handling. It measures carbon monoxide (CO), hydrogen sulphide (H₂S) and oxygen (O₂). We use it for example in the GOLIATH or in the OLLI.

This sensor is also used in safety, environmental diagnostics, process control and medical technology.

Semiconductor sensor

A semiconductor sensor is a temperature sensor with semiconductor materials of metal oxides. In the course of the measurement, the sensors are heated up so that intrinsic conductivity occurs, since a semiconductor only conducts electricity at certain temperatures. The gas molecules hit the semiconductor surface, causing a change in electrical resistance, which in turn can be measured.

The areas of application of the semiconductor sensor are safety engineering, quality assurance, process measurement technology and emission and airborne goods monitoring. The advantages of this sensor are its high sensitivity and long life. Semiconductor sensors have an extremely low power consumption and low selectivity, as other gases outside the measurement can also accumulate on the surface.

The sensitivity of semiconductor sensors can be temporarily reduced or permanently damaged by exposure to sensor poisons or inhibitors. Inhibitors include hydrogen sulphide, silicone vapours, oils, phosphate esters, halogens and other chemical substances.

We use semiconductor sensors in our HUNTER series and in the GasTest delta3 because they have a high sensitivity in the ppm range and can detect very low concentrations of combustion gases.

Thermal conductivity sensor

Gas concentrations can be determined with the use of a thermal conductivity sensor, because gases have different thermal conductivity. If a gas flows around a heated wire, it cools down according to the thermal conductivity of the gas. The wire then changes its resistance. This change can be measured and displayed.

The measurement of the thermal conductivity is not accurate enough for measurements in the LEL range. An advantage of the thermal conductivity sensor is that it does not require oxygen for measuring gases.

Common application: Measuring gas with high concentrations.

Light gases such as hydrogen or helium can also be detected highly sensitively via the thermal conduction sensor. The HUNTER Tracer Gas, for example, is a measuring device that can be used to locate traces of hydrogen. Thermal conductivity sensors are also used in the SIGI-EX and OLLI measuring devices.

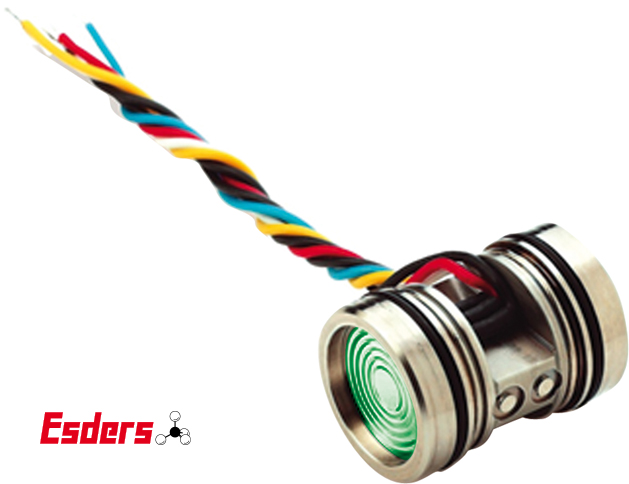

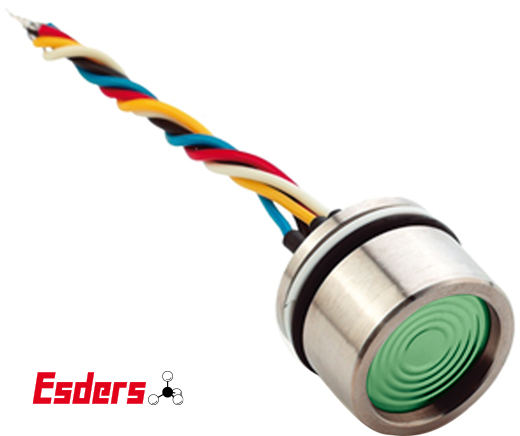

Gauge pressure sensor (low pressure sensor, mbar)

With the help of this sensor the pressure is measured in comparison to the ambient air pressure. The change in pressure is observed by the deformation of a membrane. One side of the membrane is exposed to the test pressure, the other side to the ambient pressure. The result of this measuring principle is the pressure difference to the ambient pressure. The relative pressure of a system which is connected to the atmosphere (e.g. a gas pressure regulator in a house) is the absolute pressure plus the air pressure. If I can measure both quantities, I can calculate the relative pressure.

The air pressure fluctuates due to changes in weather conditions, i.e. a change in air pressure has a direct effect on the test result.

Field of application: Measurement on regulators and house installation. Since only relatively short pressure tests take place in the house installation, the leak test and the load test, a change in air pressure only has an effect under very unfavourable circumstances. We use gauge (relative) pressure sensors in our devices GasTest delta3 and LeckOmiO.

Absolute pressure sensor (high pressure sensor, bar)

In absolute pressure sensors the internal side of the sensor is evacuated and hermetically sealed. The measured deformation of the membrane always consists of the pressure difference from the test pressure to the vacuum and is therefore independent of the ambient pressure. The measured result is therefore always the pressure difference to the vacuum.

For the pressure test is to be observed: Gases heat up by compressing air – compression. Afterwards an adaptation time is necessary for cooling down, so that the pressure in the pipeline drops. The drop in pressure is due to the cooling of the air to the ambient temperature. We have described the physical properties of gases in detail in our blog post Basics – Pressure tests on gas pipes.

The absolute pressure sensor is used for pressure tests on pipelines. External absolute pressure sensors are used when working with our smart memo and GasTest delta3.