The annual gas inspection is an integral part of responsible building maintenance. It is simple to carry out, but crucial for safety. Chimney sweeps often perform this task on behalf of homeowners or as an additional service. This work requires a keen eye and reliable documentation. This is exactly where Esders’ TONIs come into play.

What is a gas system inspection and why is it so important?

According to the Technical Rules for Gas Installations (TRGI), a gas inspection is an annual visual inspection of all exposed gas pipes in a building. The aim is to detect damage at an early stage and prevent hazards, because even minor defects, such as inaccessible shut-off devices or incipient corrosion, can have serious consequences in an emergency.

The inspection includes:

✅ Freely laid pipes: Visual inspection for corrosion, damage or changes

✅ Shut-off devices: Are the main shut-off devices, i.e. the shut-off device behind the house connection and the meter shut-off, freely accessible?

✅ Concealed pipes: Is ventilation provided?

✅ Gas appliances & air supply: Are the appliances working? Is there sufficient combustion air supply?

Whoever carries out the gas inspection, whether the owner, a specialist company or a chimney sweep, must document it. It is precisely this documentation that becomes decisive evidence in the event of damage.

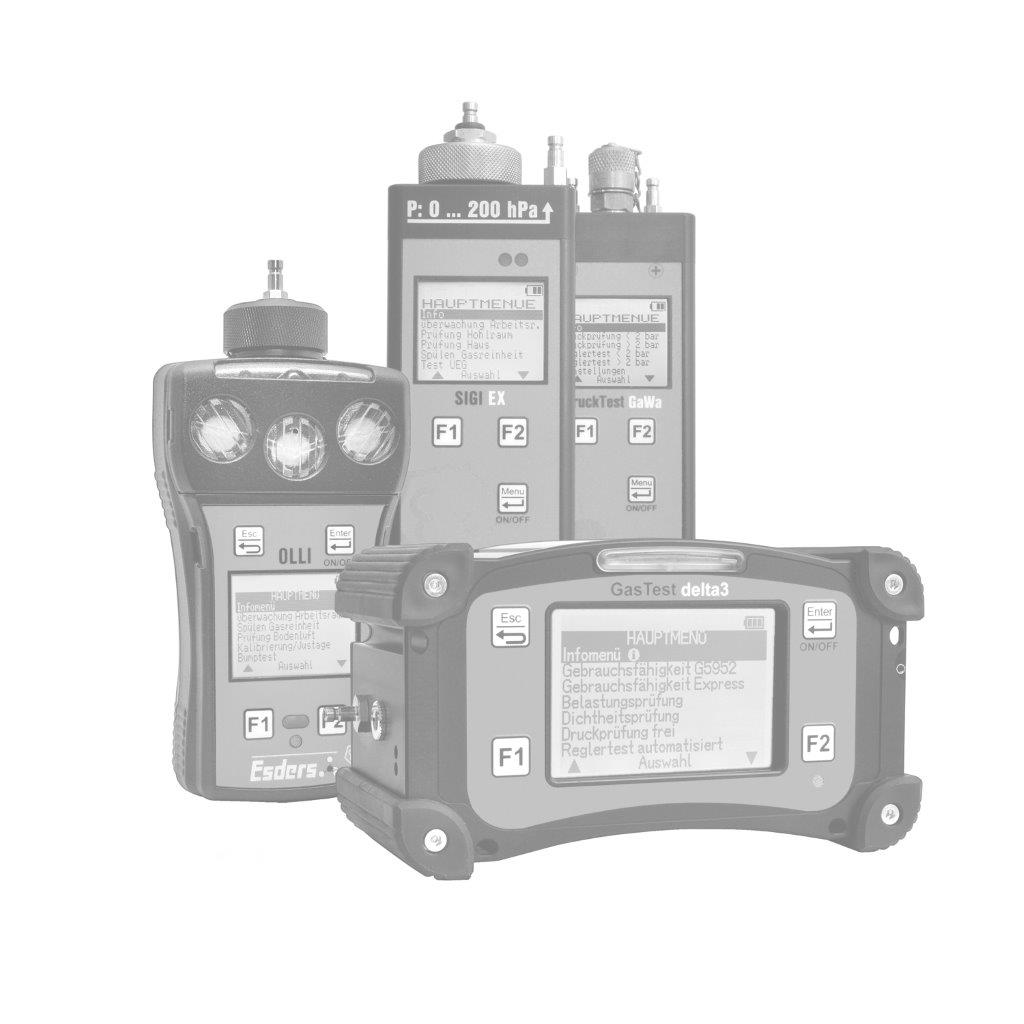

TONI GasTest CH4: Detect even the smallest leaks

Even though the gas inspection is not an active leak detection, many chimney sweeps and utility companies offer their customers an optional leak check. The TONI GasTest CH4 provides additional safety, especially on gas meters, fittings or in areas that are difficult to inspect, thanks to its flexible gooseneck.

With its high sensitivity to methane, easy use and clear digital display, the TONI GasTest CH4 is perfect for quick and selective checks. The measured values can be stored and documented directly.

Request a 15-minute presentation of TONI (online or on-site)

Invest just a little time and get all the information you need

In a concise live presentation (online or on-site), we will show you how the TONI FlowTest accelerates your testing processes and ensures standard-compliant documentation. Fill out the form now and request your personal appointment.

Advantages for chimney sweeps:

🟩 Precise CH4 measurement for additional safety

🟩 Compact, lightweight, robust – ideal for on the go

🟩 Documentation possible directly on the device

🟩 Visual and audible signals for easy handling

Systematic visual inspections with TONI

Chimney sweeps who register digitally for gas inspections and work with smart equipment are positioning themselves as modern service providers offering real added value.

With the TONI GasTest CH4 and the TONI PressureTest LP, visual inspections and optional tests can not only be carried out professionally, but also digitally documented – in line with TRGI requirements and customer expectations.

Good to know!

How gas system inspection and serviceability testing complement each other effectively

What is the difference between a gas system inspection and a serviceability test?

Even though gas inspections and serviceability tests are often mentioned in the same context, they fulfil different purposes and are carried out by different trades.

Gas inspections are part of a chimney sweep’s daily work and are usually carried out annually. During these inspections, the gas installation is visually checked for any abnormalities: pipe layout, accessibility, odour, corrosion and the condition of fittings.

The serviceability test, on the other hand, is a technical measurement and is carried out by fitters or HVAC specialists. It is mandatory every twelve years and determines whether and how much gas is escaping from the pipe. This supplements the purely visual gas inspection with a precise metrological evaluation.

Both tests together ensure maximum safety: the chimney sweep detects any abnormalities, while the HVAC specialist measures, evaluates and repairs.

Can regular inspections of gas systems replace serviceability tests?

Operators remain obliged to carry out serviceability tests every 12 years, which cannot be replaced by regular gas system inspections. Only a combination of both types of inspections can guarantee that the gas system has no visible defects and is technically leak-proof and serviceable.

Be the first to know about our new TONIs!

Subscribe to our newsletter .

.jpg?width=100)