Table of Contents

Acceptance tests for pressure sewer pipes

In previous blog articles, we have already addressed the topic of sewage networks and provided general information on this subject: Basics of sewage networks in Germany. Detailed information on the testing of wastewater pipes and components can be found in the blog article EN 1610 – Leak testing of wastewater pipes. This standard specifies the relevant regulations and test procedures that currently apply to the sewage network in Germany. To ensure that the sewer network functions properly and remains watertight in the long term, an acceptance test is mandatory after the construction of a new sewage system. This means that new gravity pipes and sewers (including manholes) must be tested for leaks in accordance with EN 1610 (e.g. using the level measurement method), while pressure sewers must be tested for leaks in accordance with EN 805. In this blog, we focus on testing existing pressure sewers.

What is a pressure sewer pipe?

Pressure sewer pipes or pressure pipelines are used, for example, on individual properties for property drainage if adverse or local conditions do not allow drainage via gravity pipes. Domestic drainage is then carried out as so-called pressure drainage via a small domestic pumping station, which pumps the sewage into the public sewer system via a pressure pipeline.

The same principle is used on a larger scale in the public sewage network. Pressure sewer pipes are used wherever gradients or significant differences in height prevent the use of gravity pipes. Larger sewage pumping stations and pressure pipes are operated, for example, in lower-lying residential areas. A gravity pipe system collects domestic sewage from the residential area in a central pumping station. From there, the sewage is pumped via a pressure pipe into the higher-lying gravity system and transported on to the sewage treatment plant.

Sewer pressure pipes are made from a wide variety of materials, the most common being PE, PVC, cast iron, steel or asbestos cement.

What regulations apply to pressure sewer pipes?

In Germany, the entire sewage network is subject to the Water Resources Act (WHG; German: Wasserhaushaltsgesetz). In addition, pressure sewer pipes and sewage pumping stations are subject to the Act on Installations Requiring Monitoring (ÜAnIG 2021; German: Gesetz über überwachungsbedürftige Anlagen). Due to the internal overpressure, pressure sewer pipes are considered pressure systems and are therefore classified as installations requiring. Strict regulations apply to installations requiring monitoring. Among other things, the ÜAnIG states: “The operator of an installation requiring monitoring must ensure that the installation is inspected to verify that it is in a safe and proper condition.” This inspection must be carried out “at regular intervals”.

The regular inspection refers to the testing of the functionality and tightness of the installation.

Many pressure pipelines in Germany are now ageing and some have been in operation for several decades. The pipeline material suffers over time due to ageing and wear caused by solids and deposits. The stability of the pressure pipe can also be reduced by the frequent pressure loading and unloading processes when the pump in the pumping station is restarted and the associated pressure surges.

In view of the high potential risk to people and the environment posed by leaking wastewater pipes, regular leak testing is advisable in order to detect even small leaks and, if necessary, to repair the pipes.

How can a recurring inspection of wastewater pressure pipes be carried out?

Recurring inspections of pressurised sewer pipes to assess their ‘proper condition’ can be carried out using various methods. These methods are relatively costly for operators of pressure sewer pipes and do not always provide a clear result regarding the actual condition of a pipe. This means that operators are currently faced with a difficult task: they must inspect pressure pipes regularly, but how can this inspection be carried out in a meaningful way?

The following are some of the procedures commonly used to inspect wastewater pipes in operation:

- Permanently installed measurement technology: Analysis of pump data, e.g. current consumption, pressure, flow rate;

- Visual inspection (e.g. inspection with camera): Commonly used for gravity sewers, but unsuitable for pressure pipes due to various factors, such as small pipe diameters and large distances between manholes, etc.

All previous procedures have the disadvantage that minor leaks cannot be reliably detected.

Only with a suitable leak test can leaks be detected and the tightness of pressure pipes be confirmed.

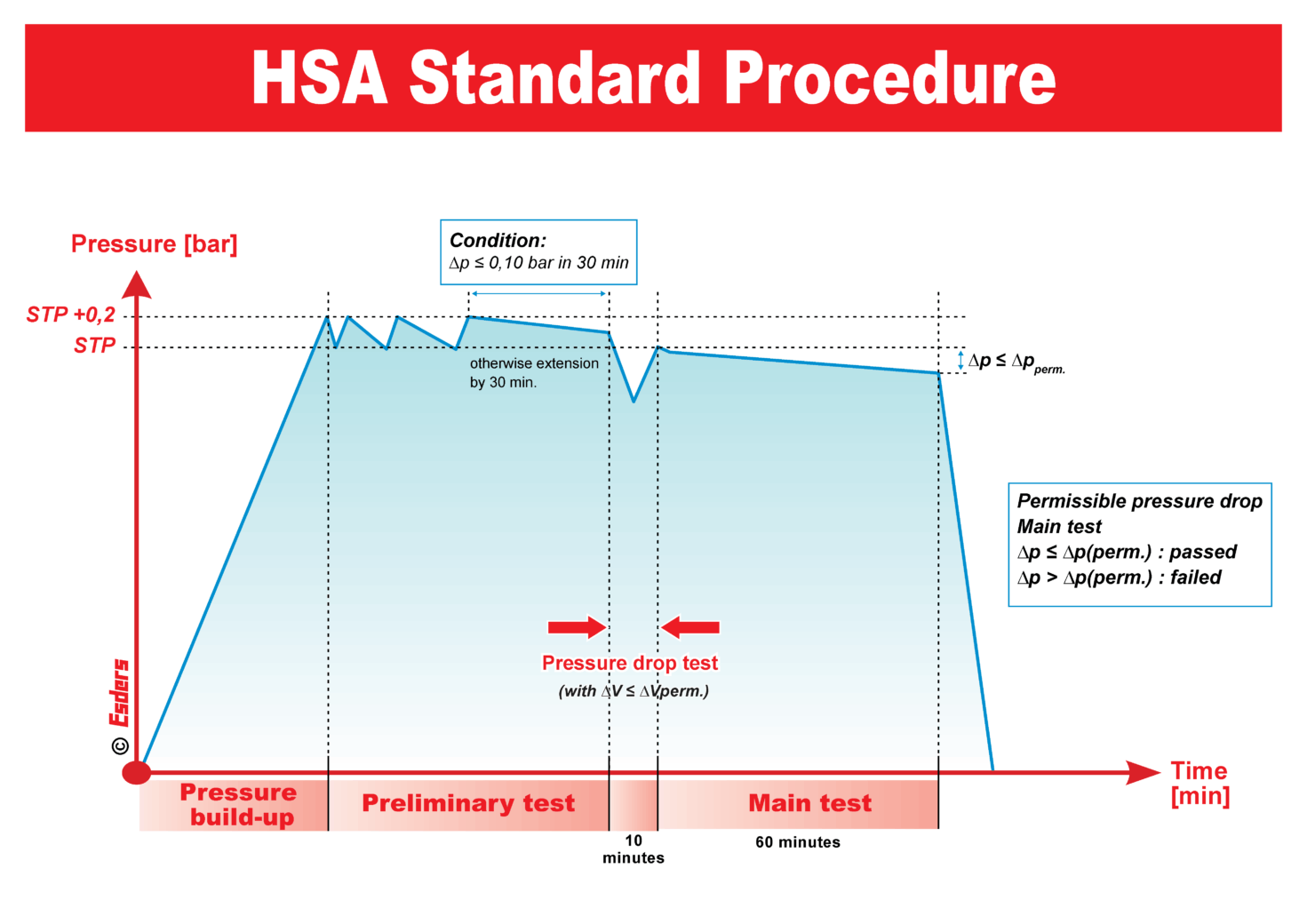

Test procedure for pressure sewer pipes developed by Augsburg University of Applied Sciences - HSA Standart Procedure

As there were no suitable procedures for testing the tightness of pressurised sewer pipes, Technical University of Applied Sciences Augsburg (HSA; German: Hochschule Augsburg) was commissioned by the Bavarian State Office for the Environment to develop such a procedure. The aim was to develop a procedure for wastewater pressure pipes in operation that combines technical feasibility, minimal downtime for the pipes in operation and reliable leak testing. This project ultimately resulted in the HSA standard procedure and the HSA 20-minute test.

The smart memo offers the appropriate test sequence for performing a proper HSA standard procedure via the HSA Wastewater option (coming soon to the product shop), which is fully automatic, compliant with regulations and reliable.

Don’t miss any news about our products and new regulations!

Subscribe to our newsletter.