Table of Contents

Why is geothermal energy so important?

In times of a tense energy market, the use of renewable energy sources is gaining increasing significance. In addition to photovoltaics and air heat pumps, geothermal energy is becoming particularly important for private households. It enables the sustainable use of heat energy stored in the ground and thus makes an important contribution to the energy supply of the future.

The thermal energy stored in the ground (geothermal energy) is extracted using borehole heat exchangers (BHE). A heat transfer medium is fed through the geothermal probe via closed pipe systems, which absorbs the energy stored in the ground and transfers it to an above-ground heat pump.

With the steadily increasing demand for climate-friendly heating solutions, the number of geothermal borehole heat exchangers drilled and installed in Germany is also rising continuously. As their use becomes more widespread, the requirements for safety, quality and environmental compatibility of the systems are also increasing.

In order to ensure reliable and safe operation, testing the geothermal borehole heat exchangers before commissioning is not only advisable, but necessary.

Why should a borehole heat exchanger be tested before commissioning?

Geothermal probes are technical installations that are inserted into boreholes up to several hundred metres deep, for example. BHE usually consist of high-density plastic pipes (e.g. PE-X, PE 100-RC), which are installed in the ground in the form of a U-probe (simplex) or two U-probes (duplex). In the following, we will focus on deep boreholes, as these are used much more frequently due to their lower space requirements (compared to surface probes).

Once the deep borehole has been completed and the BHE probe installed, the boreholes are filled with a heat-conducting and sealing compound (grouting material) to ensure both optimum heat transfer and protection of the groundwater. Immediately after backfilling, a leak test should be carried out on the BHE probe.

A leak test prior to commissioning serves several important purposes:

1. Safety and environmental protection

Even the smallest leaks in the probe circuit can cause heat transfer fluid to escape into the ground. As these fluids usually consist of water-glycol mixtures, they pose a potential risk to groundwater if they escape uncontrolled.

A proper leak test ensures that the closed circuit of the probe functions reliably and that no environmentally hazardous substances can escape.

2. Ensuring service life

Borehole heat exchangers are designed to have a service life of several decades. An early leak test helps to identify installation defects, material damage or faulty welds before the probe is put into operation and the system is backfilled.

This ensures long-term operational safety and avoids costly repairs or refurbishment.

3. Compliance with legal requirements

Depending on the country and the depth of the borehole, the construction and operation of borehole heat exchangers are subject to various legal regulations. These usually include an obligation to carry out leak tests in accordance with specified procedures (e.g. in accordance with VDI 4640 Sheet 2 or DIN EN 805).

The test not only serves as quality assurance, but also as proof to the authorities that the system complies with technical and environmental requirements.

But which regulations and rules apply to the leak test of BHE and how should the test be carried out in detail?

Legal requirements and regulations for leak testing of borehole heat exchangers

Geothermal technology has been established for a long time and is anything but new. Nevertheless, there are still very few specific regulations governing the testing of borehole heat exchangers. This is probably due to the low profile of the geothermal sector as a whole to date. However, based on feedback from our customers, we are seeing increased interest in testing technology for BHE. Below, we provide an overview of the current regulations governing the testing of BHE.

VDI 4640 (06/2019)

VDI 4640 Sheet 2 is a reasonably up-to-date guideline from the Association of German Engineers, which mainly deals with the installation, construction and commissioning of heat pump systems. In terms of content, this guideline contains little helpful information on testing a BHE. Construction and earthworks should be carried out in accordance with relevant regulations, e.g. W 400-2 or EN 1610. It is required that the entire system undergo a pressure and flow test in accordance with Paragraph 7.3.9 before commissioning (and before backfilling). The section on pressure testing itself then refers to further regulations, stating that pressure tests must “always be carried out in accordance with DIN EN 805 or comparable standards, e.g. SN 565384/6*SIA 384-6“.

DIN EN 17522 (03/2025)

The Bavarian State Office for the Environment has published information sheet N3. 3.7/2 “Planning and Construction of Borehole Heat Exchangers” from 2012. This information sheet also provides helpful information on the planning, construction and commissioning of BHE. A leak test of the entire system is required after grouting, but no details are provided; instead, reference is made to “recognised rules of technology (see VDI 4640, Sheet 2)”.

Other regulations

There are many other regulations containing information and requirements for the installation and commissioning of the borehole heat exchangers, which cannot all be listed here. If any of these documents contain information on the final pressure test of BHE, they either lack specific details, refer to VDI 4640 Sheet 2 (e.g. in DIN 4279, discontinued) or simply refer to the performance of a pressure test §in accordance with EN 805” (e.g. in GeoBerichte 24 (08/2022): Guide to geothermal energy use in Lower Saxony).

SIA 384/6 – Leak testing of BHE based on EN 805 contraction method

As explained in previous sections, many existing standards lack specific details on how to perform a final leak test on borehole heat exchangers. However, everyone agrees on one thing: a pressure test to check for leaks should be carried out at the end, and this should be done in accordance with the contraction method described in EN 805. But what does this EN 805-based procedure look like in concrete terms? What adjustments can/must be made? Can the contraction method, with all its special features, be “simply” transferred to a pipe that is several hundred metres deep?

These questions are not easy to answer, and pressure tests using the contraction method in accordance with EN 805 should be carried out on borehole heat exchangers with careful consideration. The risk of damage to the BHE due to an improperly performed test would be too great. There are a number of things to consider, particularly when selecting the test pressure. The ratio between internal and external pressure, which varies depending on the depth of the BHE, plays a key role here.

We would therefore like to highlight the SIA 384/6 “borehole heat exchangers” standard at this point. This Swiss standard deals with the planning, execution and operation of borehole heat exchangers. With regard to pressure testing in particular, the standard provides comprehensive, specific details and a special procedure for leak testing borehole heat exchangers, which was developed over many years as part of a scientific study on the “Evaluation of leak testing for borehole heat exchangers according to SIA 384/6”. The reliability and applicability of the procedure has been proven by measurement data, practical tests and the underlying study.

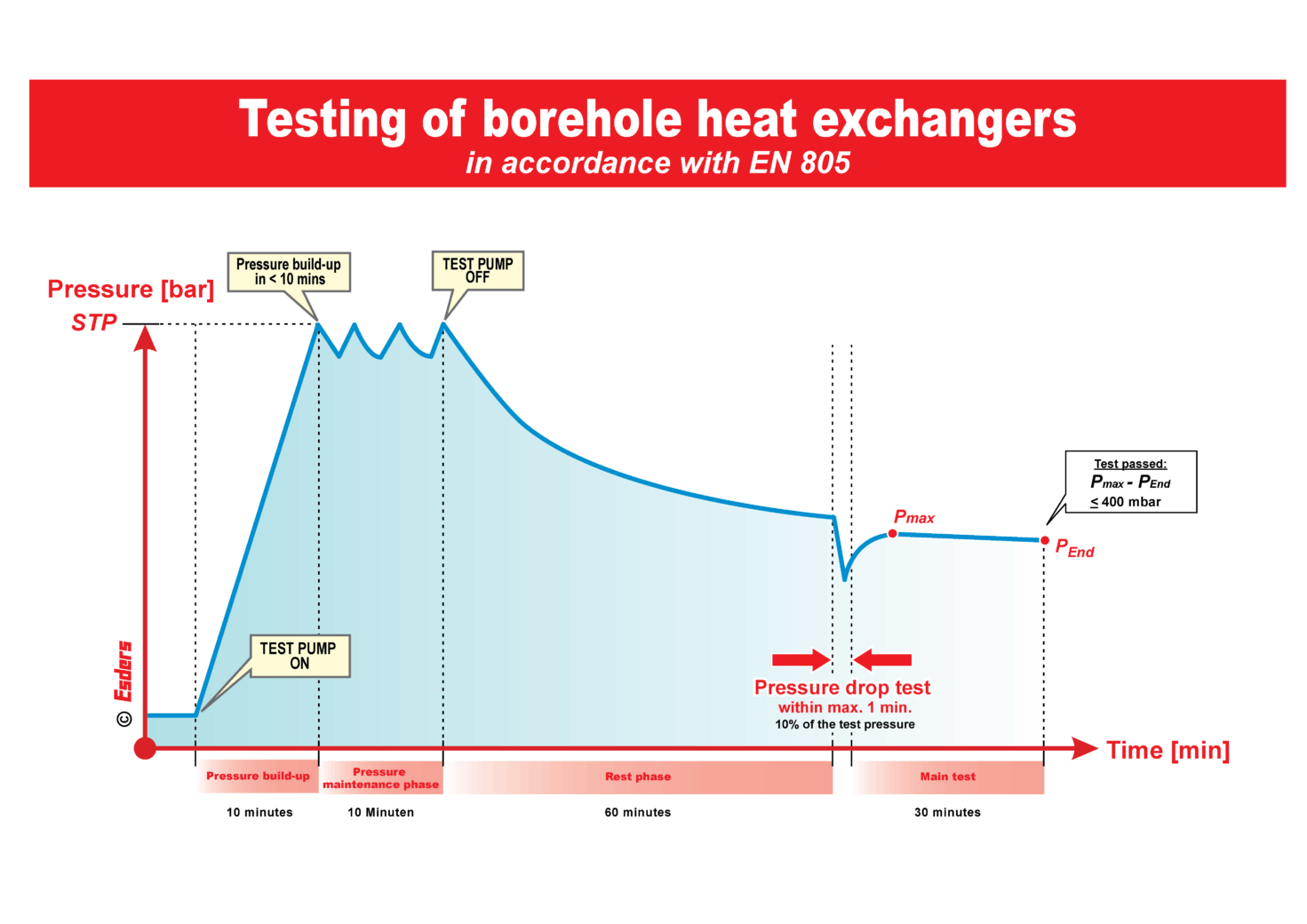

The procedure is based on the contraction method in accordance with EN 805 and includes specific adjustments to the special conditions of a BHE. For example, the maximum test pressure is determined depending on the depth of the BHE or the density of the backfill. Test times, limit values, etc. are also adapted for use with BHE. For an initial overview of the procedure, which we expressly recommend at this point, see the illustration below:

Option: Borehole heat exchanger testing in accordance with EN 805

Our smart memo is the ideal choice for carrying out leak tests in accordance with specified test procedures. We already offer standard-compliant, partially automated procedures for testing water pipes, gas pipes, wastewater pipes, etc. For the geothermal sector, we now also offer the option of testing borehole heat exchangers in accordance with EN 805. This option includes a menu-guided test procedure for pressure testing of borehole heat exchangers. The details of the test have been implemented in accordance with the contents of SIA 384/6. The procedure is therefore also compliant with all other applicable standards that require compliance with EN 805.

smart memo guides the user through the entire test. This means that the user does not need to know all the details of the procedure; smart memo will do everything for you! With the help of optional items, the procedure can be carried out fully automatically, similar to the fully automatic contraction procedure according to W 400-2.

Don’t miss any news about our products and new regulations!

Subscribe to our newsletter.