Table of Contents

One of the most important sets of rules and regulations in the field of pressure testing in Germany receives an update.

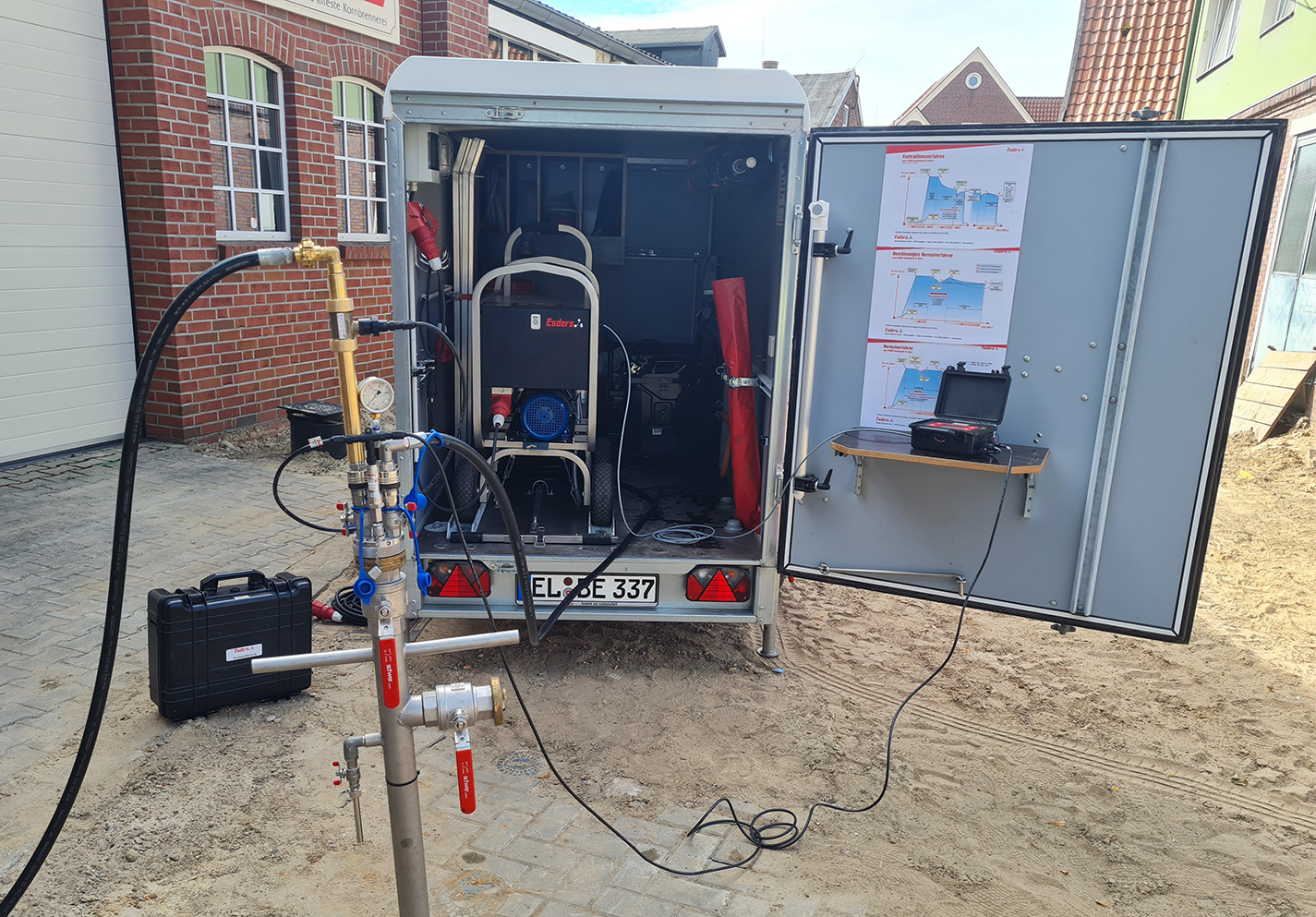

DVGW worksheet W 400-2 (latest version from 2004) contains technical rules for water distribution systems, especially with regard to construction and testing. Established pressure testing procedures, such as the contraction procedure or standard procedure, are specified in worksheet W400-2. The pressure test devices of Esders GmbH contain menu-guided test sequences for the proper execution of the procedures regulated in Worksheet W400-2. The rules and regulations have now been updated (August 2022) to reflect the current state of the technology.

Here we explain the new features and differences compared to the old version of the worksheet (from 2004).

Requirements for qualified staff

In future, pressure testing may only be carried out by a pressure testing expert. This expert must be appointed in writing by the company carrying out the work and must attend an appropriate training course every 5 years. Within the executing company, there must be at least one such expert who either carries out the pressure test himself or at least supervises the pressure test after training/instruction of employees.

Requirements for measuring technology

With the update of the worksheet, stricter requirements are placed on the measuring technology than before. In the course of further developments in the field of sensors and measurement technology, whereby significantly higher measurement accuracy and stability are possible and common, this is a sensible adaptation of the regulations to the state of the art.

Pressure sensors

In future, the accuracy of the pressure sensor used must be at least 0.1% of the measuring range. In addition, the measuring range of the sensor must not be greater than 30 bar (for test pressures up to STP = 21 bar) and not greater than 50 bar (for test pressures up to STP = 45 bar).

The measured value resolution must generally be better than or equal to 10 mbar, i.e. must not be displayed coarser than in 10 mbar steps.

Temperature sensors

Overall, when updating the worksheet, an attempt was made to clarify that temperature fluctuations of the pipeline in the course of the pressure test can have an influence on the result. Therefore, temperature fluctuations should be avoided as far as possible. In addition, a general upper temperature limit for plastic pipes (20°C) and a lower temperature limit for all pipes continue to apply.

In order to be able to evaluate the influence of temperature fluctuations on the test result, at least one representative temperature measurement (e.g. ground stake or contact sensor) per test phase will be required in the future. For the use of pressure test devices such as the smart memo, this means in effect that temperature sensors must be permanently connected and used.

The measuring range of the temperature sensors used was not specified. The measuring accuracy as well as the resolution of the sensor should be at least 0.1°C (0.1K).

Flow meters/water meters

The pressure drop test is used in the field of water pressure tests as an aid to checking that the pipeline is free of air. During the pressure drop test, a targeted pressure drop must usually be generated, e.g. by 1 bar. The necessary amount of water to be discharged must be measured and compared with a permissible amount of water.

With the publication of the updated worksheet, strict requirements are imposed on the measurement of water quantity. Measuring cups may no longer be used, it must be a logging electronic measuring device, i.e. it must generate a printout. Furthermore, when using “result-assessing testing devices” (e.g. smart memo), the measured value of the water quantity must be transmitted electronically.

The measuring accuracy of the digital flow meter/water meter must be at least 5% of the measured value.

Calibration of the measuring devices

As before, measuring devices must be calibrated and checked regularly. For the calibration of the measuring devices used, an interval of no more than 2 years has been specified in the worksheet. If manufacturer recommends a shorter interval, this should be observed.

In the following blog post on the W 400-2 series of changes, the differences and innovations of the individual procedures are shown in comparison to the 2004 worksheet.

Always be up to date with the latest DVGW regulations!

Enter your contact details in the form and our technicians will contact you immediately. Don’t miss any important changes to DVGW Code of Practice W 400-2 (as of 2022) and ensure that your installations comply with the latest standards.

Don’t wait any longer – fill in the form and let us help you!