Table of Contents

In addition to water, wind, solar and geothermal resources, biomass is also a renewable energy source. The percentage share of bioenergy in gross electricity generation in 2020 was 7.8 % (source: Statista). For renewable energy supply, biomass provides the possibility of further expansion.

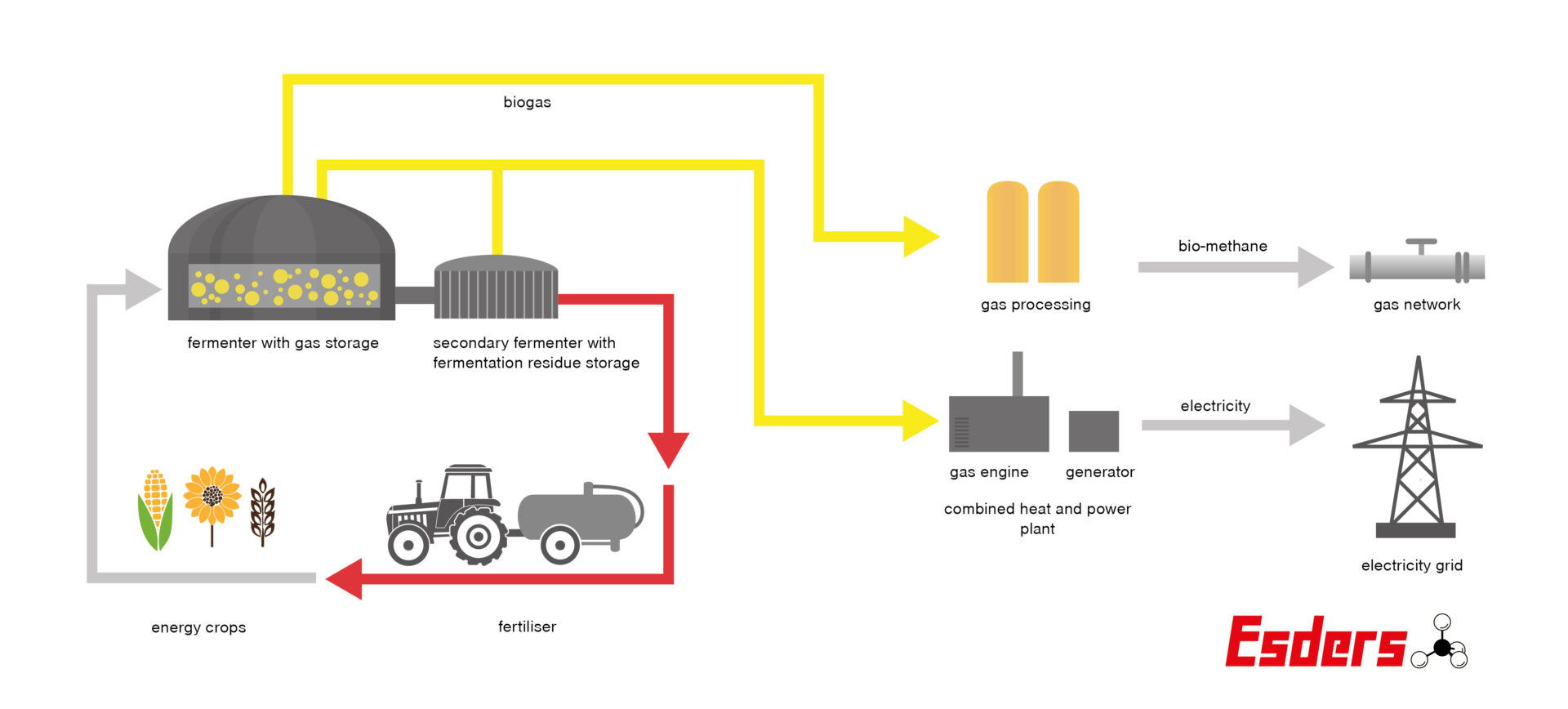

Renewable raw materials or waste materials are used to produce biogas. These are energy crops, biowaste and food leftovers, but also liquid manure and dung. In addition to generating electricity, biogas can be upgraded to natural gas quality. Therefore, it can be used with little effort using the existing infrastructure (natural gas network).

Biogas is a combustible gas produced by the fermentation of biomass in biogas plants. In practice, depending on the starting substrates (maize, grain, manure, etc.), the main components methane and carbon dioxide are formed, as well as other gases in various compositions. Furthermore, methane is an efficient energy carrier and burns in the presence of oxygen to form carbon dioxide and water.

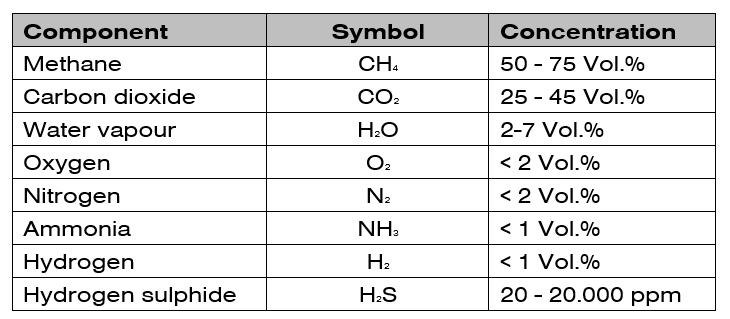

Composition of biogas

Methane is the component to be produced in a biogas plant with the greatest benefit for energy production. As CH4, carbon is present in its most reduced form. In combination with oxygen, the substance oxidises and provides energy until it is converted to carbon dioxide and water.

Carbon dioxide no longer provides energy, as this is the most oxidised carbon compound.

Water vapour is a component, like CO2, that can no longer deliver energy through oxidation.

Ammonia (NH3) and hydrogen sulphide (H2S) are also among the undesirable gas components. Hydrogen sulphide in particular is present in every biogas in measurable quantities and is usually in the range of 0 to 1500 ppm (10,000 ppm corresponds to 1 vol.%). You can read about the basics of the ppm and vol.% measuring ranges here.

A high concentration of methane and a low concentration of hydrogen sulphide are ideal.

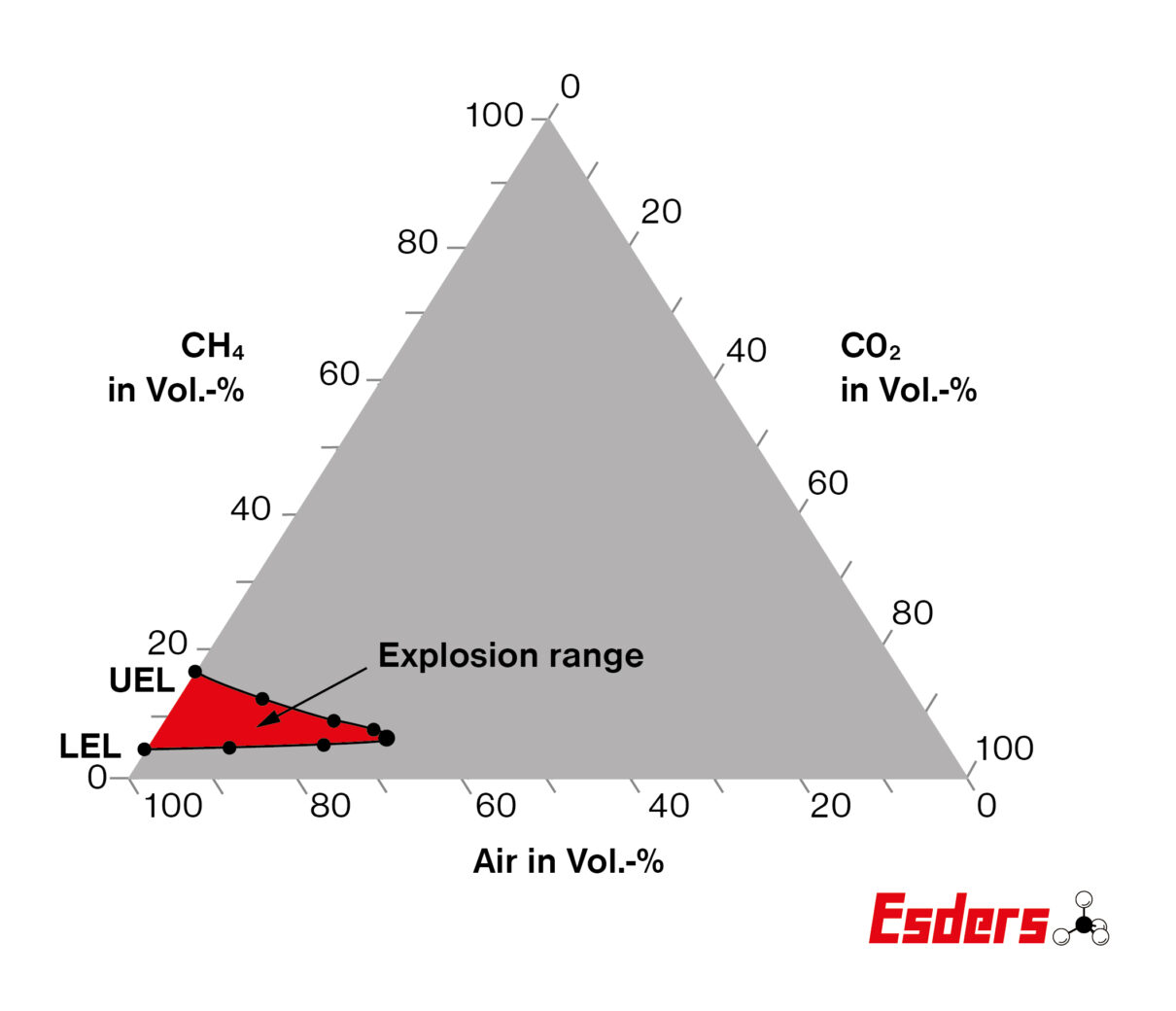

Biogas is dangerous due to the components and the resulting physical-chemical and toxic properties. Due to the methane part biogas can become extremely flammable and form a dangerous explosive atmosphere in combination with air.

Explosion range

The Ex zones on a biogas plant fall into the area of occupational health and safety and can be read about in the BG ETEM section Systematic risk assessment – Classification of explosion protection zones on biogas plants. Typical areas of these Ex zones are agitator adjustments, overpressure and underpressure safety valves and the direct container connections to the gas foil. These are often easily accessible through platforms, podiums or ladders. In addition, gas is always to be expected at gas-carrying lines, in shafts and especially in pre-pits. Appropriate personal protection measures should be taken, such as wearing a gas warning device (OLLI).

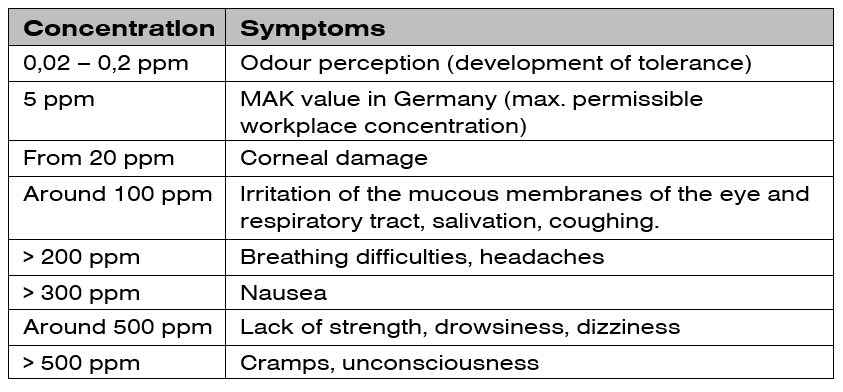

Toxic hazards

In addition to the explosion hazard caused by methane, the toxic hazards for humans should not be overlooked. The following hazards can be caused by the toxic gas hydrogen sulphide:

- Destruction of the red blood pigment and thus a paralysis of intracellular respiration.

- In contact with mucous membranes and tissue fluid in the eye, nose, throat and lungs, alkali sulphides may cause a very strong irritation.

- May cause damage to the central and possibly also peripheral nervous system.

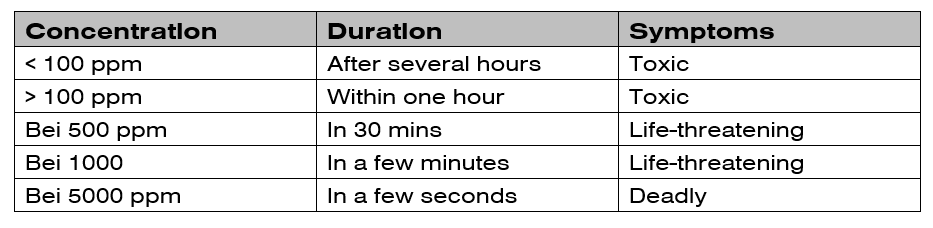

Effects of hydrogen sulphide

Toxicity in different ppm ranges

Personal protection

Due to these hazards, the use of a gas warning device for workplace monitoring is recommended for personal protection when working on raw biogas lines. The following gas constituents must be detected according to “DGUV 203-081”: Methane, carbon dioxide, hydrogen sulphide. This ensures a high level of safety. Devices in this category are intended for use in areas in which an explosive atmosphere is likely to occur. We recommend the use of an explosion-proof multi-range measuring device (OLLI with IR + H2S sensor). The essential functions to be executed for personal protection when working on or at biogas plants are ensured by monitoring the working environment for the approach of the lower explosion limit (LEL) and the exceeding of certain concentrations of toxic gases.

In one of our next blog posts on biogas, we take a closer look at the analysis of biogas and the associated quality.