Gas installations must be safe, leak-proof and reliable at all times, whether in residential buildings or larger utility structures. For installers and network operators, this means recurring inspections, documentation and working efficiently at the same time.

The problems are well known: various inspection procedures, different devices and the issue of time loss in everyday working life in the plumbing, heating and air conditioning sector as well as in utilities. In addition, the TRGI and DVGW G5952 do not necessarily make the requirements any clearer.

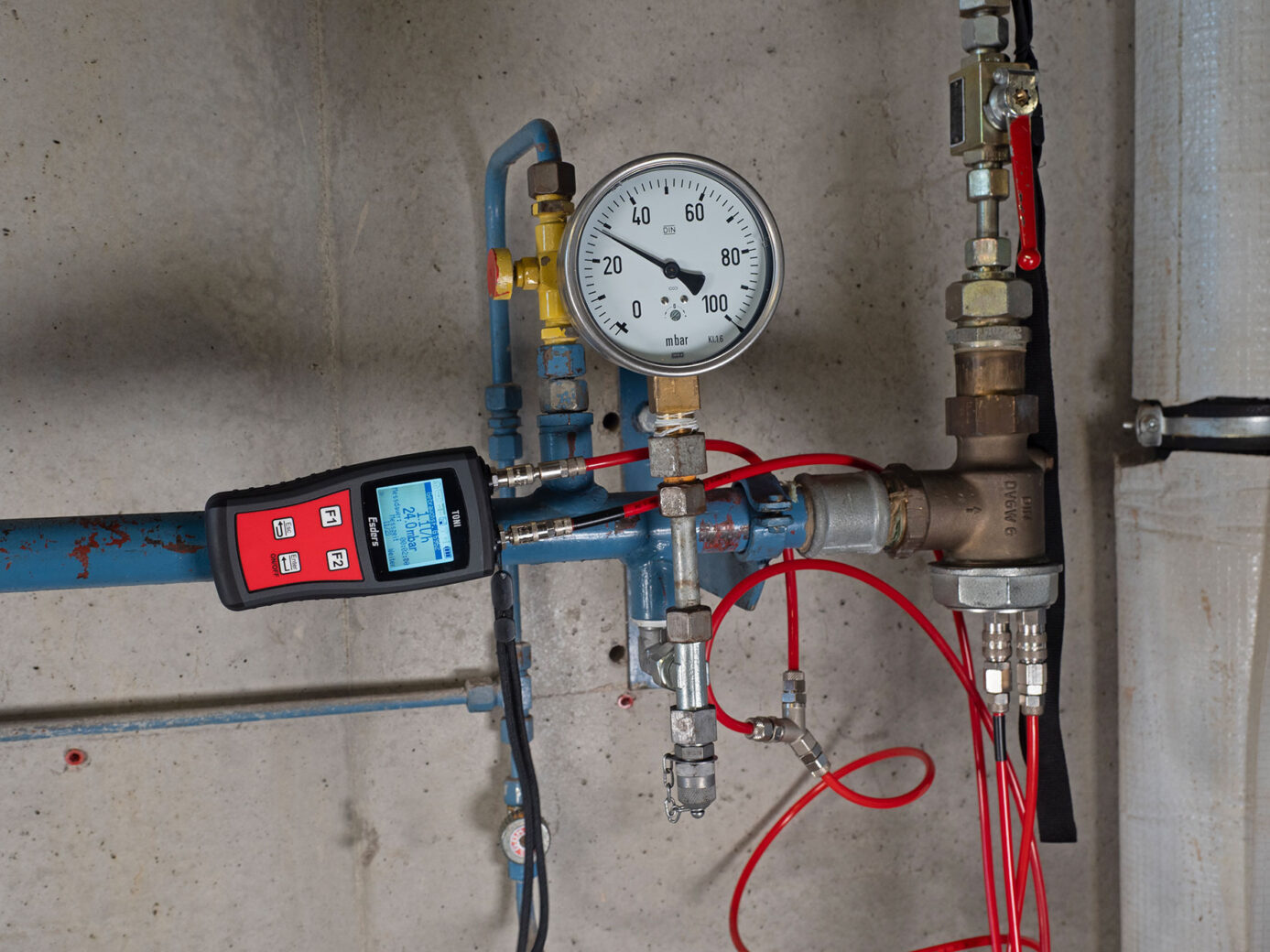

TONI FlowTest as a solution

This is where our TONI FlowTest comes in, which combines:

- Flow measurement

- Leakage measurement for a serviceability test in accordance with G5952

- Load and leak testing

All in one device solution, including digital documentation.

Request a 15-minute presentation of TONI (online or on-site)

Invest just a little time and get all the information you need

Reliable leak measurement for serviceability tests

The serviceability test serves to check existing gas pipes in operation for unacceptable leaks. It is carried out on gas installations with operating pressures of up to 100 hPa and is regulated in TRGI G600. Operators are obliged to have this test carried out by a qualified person at least every twelve years.

For the duration of the measurement, the connected gas appliances should be disconnected or closed and the pipe connected to the measuring device via a test connection. After a waiting period depending on the pipe volume, the actual leak rate is determined and displayed directly.

Load and leak testing on gas installations

A load test is primarily carried out on newly installed gas pipelines and serves to check the mechanical strength of the pipe connections. The pipeline is subjected to a significantly increased test pressure in order to detect material defects or weak points at an early stage. The required test pressure is built up using air or an inert gas (a gas that hardly reacts chemically). The test is carried out without any gas appliances or fittings connected, and the pipeline is not filled with operating gas.

After any work on the gas installation, a leak test must be carried out. This ensures that the system is still leak-proof before operational gas is supplied. Here too, the test is carried out with air or an inert gas. For new installations, the leak test follows the load test.

Constant monitoring during the testing process

To perform both tests, the gas pipe is closed and connected to the measuring device via a suitable test connection. Once the test pressure has been reached, a stabilisation phase begins, which gives the installation time to react. The actual test then begins. The pressure is continuously monitored throughout the entire measurement period.

If the test pressure remains constant throughout the entire test period after the stabilisation phase and no pressure drop is detected, the test is considered passed. After completion of the test, the system must be depressurised in a controlled manner. As with all test procedures on gas installations, complete and standard-compliant documentation of the measurement results is mandatory.

The TONI FlowTest guides you through the respective test procedures and automatically switches to the next test phases. The pressure is constantly monitored and logged in accordance with the specifications of TRGI G600.

The most important advantages of TONI FlowTest

✔ Serviceability test according to DVGW G 5952 (Class L)

✔ Flow measurement at operating pressure

✔ Leakage quantity display in l/h for direct evaluation

✔ Load and leak test according to TRGI (up to 2 bar)

✔ Two pressure connections – no need to reconnect

✔ Intuitive menu & clear processes

✔ >120 h battery life

✔ IP64, extremely lightweight & with magnets

✔ Digital test reports via Esders Connect

✔ Print output via thermal printer

✔ Made in Germany – with fast service

Questions from the plumbing, heating, air conditioning and utilities industry.

Answers from our TONI team.

I often change meters. Does TONI FlowTest save me time?

Yes. That’s exactly what it’s designed for. The flow measurement shows you immediately whether there is a leak and how big it is. Documentation is carried out automatically via Esders Connect.

What about large systems? 100 litres and more?

No problem. The TONI FlowTest works independently of the pipe volume and is therefore also suitable for larger building structures and utility systems.

Do I still need tables or calculations for the leakage rate?

No. The Class L measurement measures the leakage rate directly. No volume calculation, no graphical methods, no U-tube.

Can I send the results to the customer in digital form?

Yes. With Esders Connect, the test report is generated automatically — free of charge.

Options:

- Directly to the customer by email

- As a PDF for documentation

- Or printed immediately on the thermal printer

How quickly can I start using the device?

Immediately. Menu-guided procedures, intuitive operation, no complicated settings.

The device guides you through the tests — like a digital assistant. And we offer adapter hose sets for existing devices.

For utilities: Why does the TONI FlowTest increase process reliability?

Network and utility companies have special requirements:

- Repeatable tests

- Reliable documentation

- Devices that work just as well in the house connection room as they do outside

- Clear traceability for audits and quality assurance

The TONI FlowTest meets precisely these criteria:

- Automatic, audit-proof documentation

- Stable measurements regardless of pipe volume

- Robust design for daily field service

- Two gas connections for speedy work

Don’t miss the news about our new TONIs!

Subscribe to our newsletter now.

.jpg?width=100)