Table of Contents

We have been offering flaring devices or gas flares for flaring hazardous gas mixtures for many years. Since then, our mobile gas flares have been successfully used in a wide variety of applications, most of them in the field of gas supply.

In the gas distribution network, a gas flare is an effective tool for preventing operational methane emissions during expansion, decommissioning or commissioning of pipelines.

Mobile gas flares are used by our customers for the inspection of tank facilities and the dismantling of gas tank facilities, e.g. aging propane tanks. In addition, our mobile gas flares can be found in some pilot plants for researching new types of energy carriers or production processes for hydrogen or methane. There, too, hazardous gases have to be neutralised for safety reasons or other accompanying gases for environmental protection reasons. In all these applications, neutralisation of the gases takes place via targeted flaring, i.e. conversion into less hazardous or less harmful gases. Methane is converted into CO2 during flaring, hydrogen into water (H2O), for example.

Gas flare safety

But how can flaring gas actually be safe and how is it guaranteed that the flame does not “jump over” into the pipeline or tank?

Since we, as the manufacturer of the gas flare, cannot influence which gas mixture or which gas concentration is passed through the gas flare, we have decided to design the safety precautions of the gas flare for the worst-case scenario.

This means that we assume that an ignitable mixture may be present inside the gas flare under certain circumstances. To protect against flame penetration into the pipeline or tank to be protected, we install so-called flashback arresters or flame arresters in our gas flares as standard.

These components provide a high degree of safety and are an effective protection against flame arcing in our gas flares.

Flame arrester and operating pressure

In the documentation for the flame arrester, there is information on the operating pressure, e.g. max. 1.2 bar. Can I operate the gas flare at a higher pressure at all?

We use flame arresters in our gas flares that are tested and certified according to DIN EN ISO 16852. The following passage can be found in the introduction to this standard:

“3.1 Flame arrester

A device installed at the opening of a piece of equipment or in the interconnecting piping of a system of equipment, the intended function of which is to permit flow but prevent flame arcing.”

The specifications and documents of the flame arrester are designed precisely for this mode of operation. The same applies to the specification of the permissible operating pressure of the flame arrester.

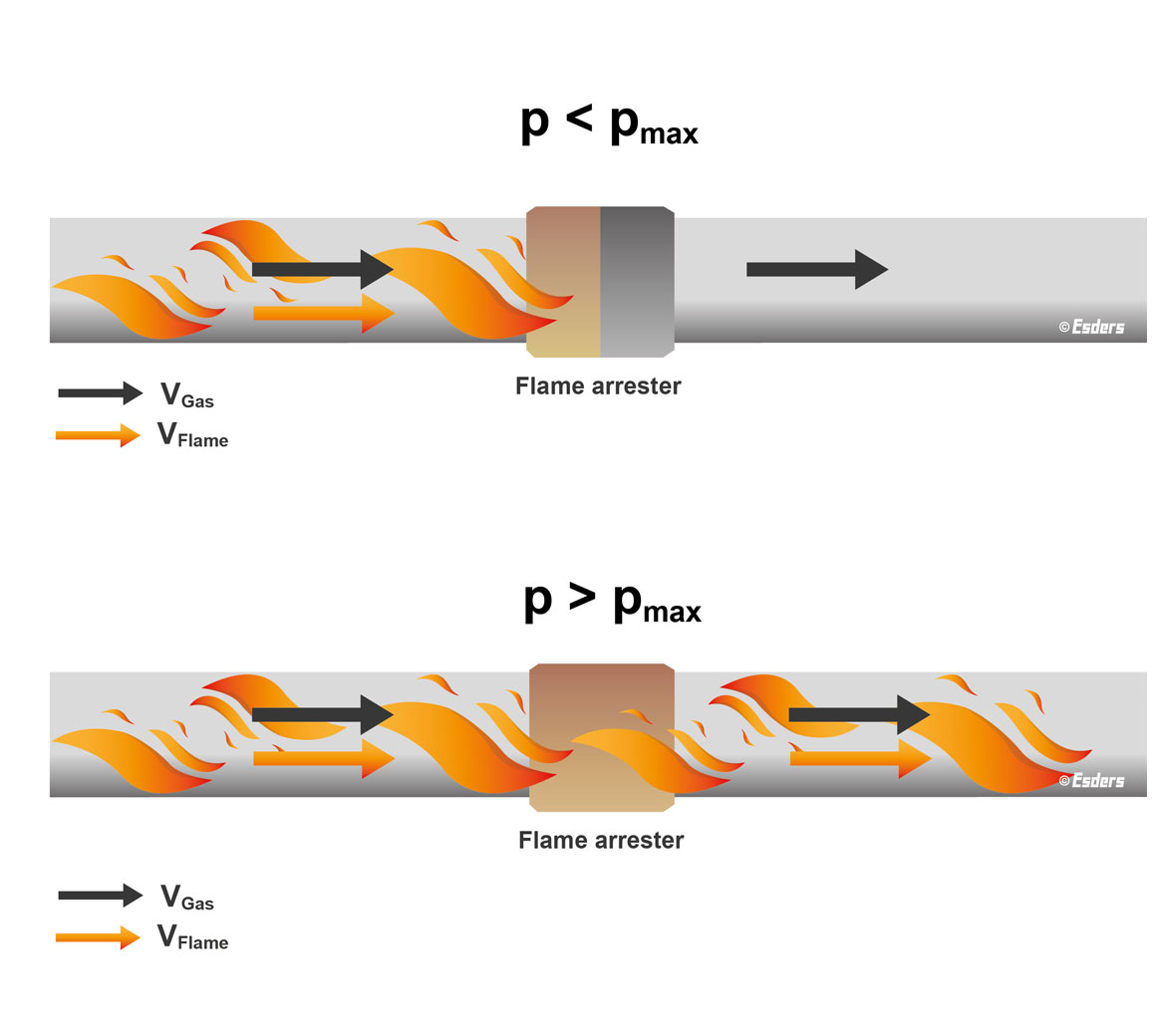

For flame arresters approved for hydrogen, the absolute operating pressure according to the standard is 1.1 bar absolute. This means that hydrogen can flow through the flame arrester at a flow pressure of 1.1 bar (i.e. approx. 100 mbar relative to atmospheric pressure), but a flame in the SAME direction of propagation is stopped by the component (see picture 1)! As soon as the absolute operating pressure is exceeded, a flashback of the flame with the flowing gas through the component is possible.

Gas test stand pipe and mobile gas flares

In our products, such as the gas test stand pipe and the mobile gas flares, the gas flow and flame source are reversed: the flame propagation AGAINST the flow direction of the medium is to be prevented. The documentation and data sheets of flame arresters are therefore not directly transferable to our application.

Flame flashback and gas flow

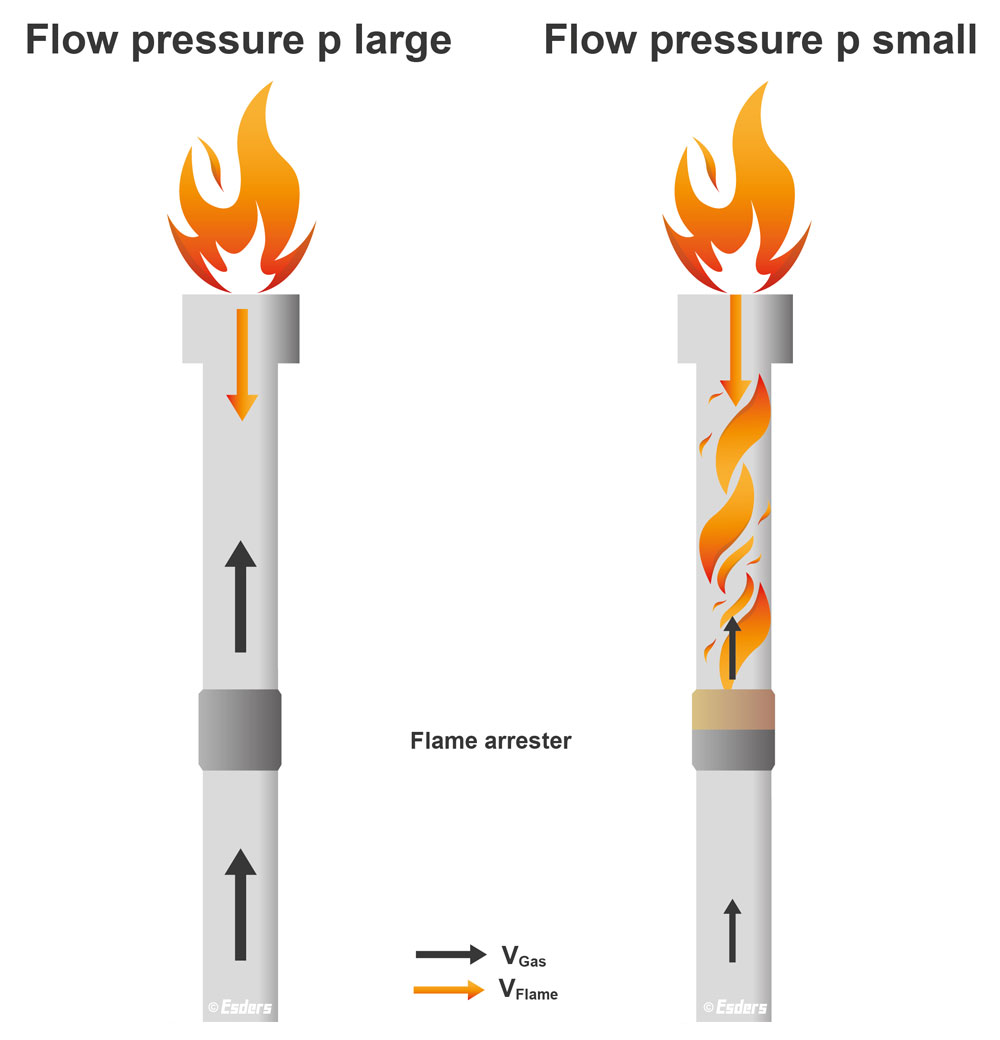

Protection against flashback against a gas flow is basically “simpler” than with the same direction of propagation. In the gas flare, with sufficient pre-pressure, flame flashback into the pipe cannot occur in principle, as the flow velocity of the escaping gas is already significantly greater than the propagation velocity of a flame. The flame speed acts against the gas flow, see picture 2 on the left.

So as soon as the inlet pressure is sufficiently high (we put this at p>100 mbar relative to the atmosphere), a flame arrester would theoretically not be absolutely necessary.

Only at a small inlet pressure (p<100 mbar relative to the atmosphere) does the flow velocity of the gas reduce to such an extent that a flame could enter the pipe, since in this case the flame velocity can become greater than the flow velocity of the gas. It is precisely for this case (low inlet pressure) that the flame arrester is needed and here it works perfectly!

As already described, the flame arrester would even stop a flame if the gas were to recede into the pipe (i.e. with the same direction of propagation, see picture 1)!

A flame arrester in accordance with DIN EN ISO 16852 is therefore an extremely safe component in a gas flare and offers much more safety than simple gas arresters.

What pressure can the flame arresters withstand from a mechanical point of view?

As already mentioned, the operating pressures stated in the documentation of the flame arresters refer to a different safety arrangement (see above). With regard to pressure resistance and tightness, all flame arresters installed in our gas flares have been tested and approved for the respective approved operating pressure of the different gas flares.

DIN EN ISO 16852 provides clear specifications for leak tests and pressure tests as part of quality assurance before delivery by the manufacturer of the products. If the maximum operating pressure of a gas flare approved by us exceeds the test pressure specified by DIN EN ISO 16852 (e.g. 20 bar for the gas standpipe or the mobile gas flare XL), we rely on assurances from manufacturers and on internal tests which ensure that the components are correspondingly pressure-resistant and tight.

Personal protection, work safety and risk analysis

Gas flaring is not an everyday measure and personal protection, work safety and risk analysis are important aspects in its implementation. It is understandable that such measures as a whole and the suitability of a gas flare are examined and discussed with great care by our customers. In the past, we have carried out many investigations, calculations and tests in order to offer a safe and functional product. In addition, we have received a lot of positive feedback on experiences with our product from customers and have personally carried out stress relief on high-pressure pipelines with our gas flares on construction sites. So, you can be confident that the safety of our products has been fully and carefully tested.

Inspection protocol for mobile gas flares

We have compiled a sample inspection protocol for our mobile gas flares and offer you the form for free download. Simply fill out the form.