Table of Contents

The German Electricity and Gas Supply Act (EnWG – from German Energiewirtschaftsgesetz) calls for safe, affordable and environmentally compatible grid operation. This requirement is specified in such a way that energy systems must be constructed and operated in such a way that technical safety is guaranteed. Technical safety requires that the gas network operators are always in a position to intervene immediately and competently in the event of faults in order to prevent damage or to repair damage that has occurred.

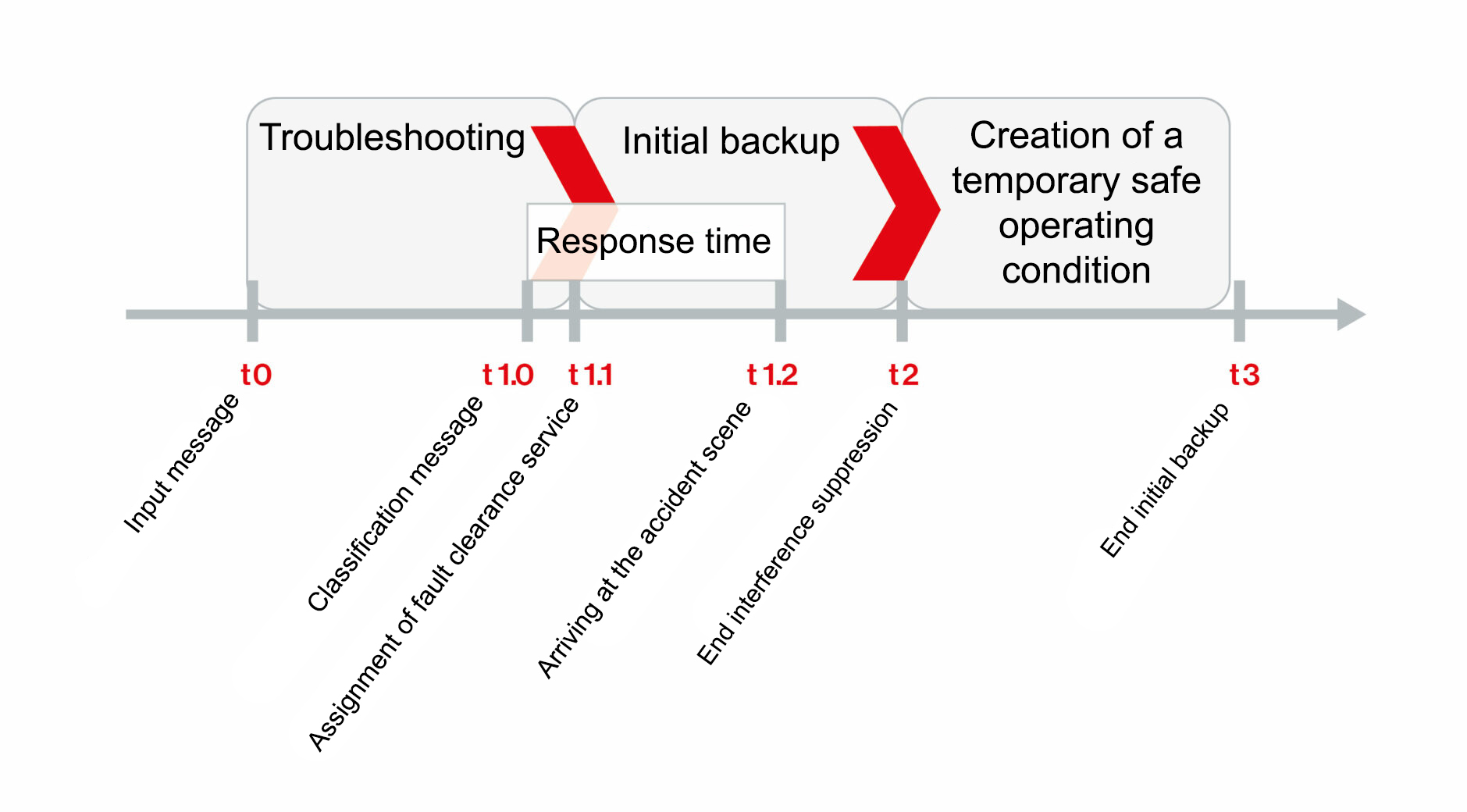

For this purpose, gas network operators must organise and maintain a fault clearance management system. According to DVGW GW 1200, fault clearance management is the process of fault clearance with the individual measures of fault detection, initial protection and restoration of a temporary operationally safe condition. This applies to both conventional and natural gas networks with an admixture of up to 20 Vol.-% hydrogen (volumetric share).

The legal obligation to set up fault clearance management also arises for gas network operators from the German Low Pressure Connection Ordinance (NDAV – from German Niederdruckanschlussverordnung) and the Ordinance on High Pressure Gas Pipelines (GasHDrLtgV – from German Verordnung über Gashochdruckleitungen).

Troubleshooting

Recognising a malfunction is the first step in the entire process. Malfunctions can have various causes or characteristics; ultimately, any deviation from the proper operating state is to be considered a malfunction.

A typical case of a malfunction, however, is the report of a gas smell from external persons (e.g. tenants, house owners). This is usually received by the reporting office by telephone, but can also be received in other ways (e.g. by e-mail). This sets a process chain in motion, at the end of which is the restoration of a temporarily operationally safe condition.

First of all, a list of questions on the type, scope and nature of the malfunction must be worked through together with the person reporting the malfunction in order to be able to classify the report immediately afterwards. The need for action and urgency can then be concluded. From this point on, the response time begins, which ends with the arrival of the fault clearance service at the location of the fault. It is a maximum of 30 minutes, subject to normal weather and road conditions.

Classification of natural gas incidents

The classification of natural gas incidents may vary depending on the context and the entity in charge of the management and supervision of gas distribution and supply. However, the following is a general classification of natural gas incidents:

- Gas leaks

- Emergencies and accidents

- Supply problems

- Maintenance and repairs

- Gas quality problems

- Metering problems

- Customer service

- Regulatory non-compliance

- Workplace safety

Initial emergency response

After classifying a received report (e.g. gas odour report), the reporting office informs the fault clearance service within the company and instructs it to rectify the fault. After arriving at the fault scene, initial actions include

- Determining the type and extent of the fault,

- Initiation of initial safety measures to avert danger,

- Feedback to the reporting office

If necessary, other external services should be informed and involved for initial safety or troubleshooting (e.g. fire brigade, civil engineering company). Depending on the type and scope of the reported fault, this can be done directly from the reporting point or upon arrival of the fault clearance service.

Technical measures can contribute to the initial protection requirements and thus contribute to the safety of the gas supply (e.g. gas flow monitors in the network connection lines).

Temporary operationally safe condition

Once the initial emergency response has been completed, the restoration of the temporary safe condition of the gas installation begins. For this purpose, repair measures may have to be carried out, for which access to additional materials and equipment must be regulated (e.g. new gas shortage protection or gas flow monitor and, if necessary, special tools for installation), so that no immediate danger or no danger continues to emanate from the source of the fault or the faulty equipment. Only once this condition has been reached is fault clearance considered complete. If necessary, this may be followed by (unplanned) repair work, which, however, does not necessarily have to be directly related in time to the fault clearance.

In addition to sufficient organisational conditions, it is indispensable to have a sufficient number of appropriately competent staff to ensure that the entire process of fault clearance runs smoothly. The necessary qualifications of the staff must be ensured through regular training and further education measures. In times of a shortage of skilled workers, this is not an easy task for network operators, but there is no alternative.